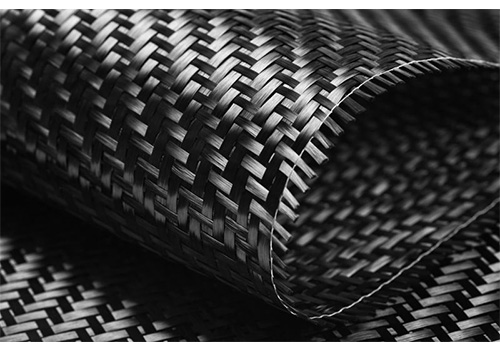

Composite materials, due to the unique performance and diverse applications, have become an important part of modern industry. Composite materials are widely used in various fields, such as aviation, construction, cars, etc. However,it is often easy to meet some problems during cutting .

Problem description:

1.Cutting accuracy : composite material is a kind of material mixed by resin and fiber. Due to the principle of tool processing,fiber is prone to peeling and causes burrs.Due to the strength and toughness of composite materials make the cutting process difficult and it is easy to produce errors, affecting the quality of the final product.

2.Tool wear: The composite material has a large wear on the cutting tool, and it needs to change the tool frequently and increase the cutting cost.

3.Operational safety issues: Improper operation during the cutting process may lead to safety issues such as fire and explosion of cutting blades.

4.Waste disposal: There are many wastes after cutting, which is difficult to deal with, which not only wastes resources, but it is easy to affect the environment.

Solutions:

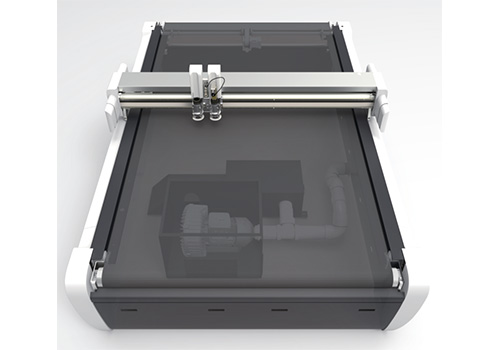

1.Use professional cutter: Using professional equipment can greatly improve cutting accuracy and efficiency.IECHO new fourth-generation machine BK4 has the high-speed digital cutting system and equipped with intelligent IECHOMC precision motion control , which the maximum cutting speed is 1800MM/S.lECHO’s newly developed air circulation cooling system efficiently dissipates heat and easily copes with harsh environments and can achieve maximum protection of materials under high-speed and precise cutting conditions.

2.Tool optimization: Select tools suitable for composite materials to reduce the wear speed of the tool.

UCT:UCT can cut materials up to 5mm thickness with fast speed.Comparing with the other tools, UCT is the most cost-effective tool. It has three types of blade holders for different blades.

PRT:Compared with DRT, the PRT with its strong power performance is suited for wider range of materials, can cut easily the materials like glass fiber and aramid fiber. It has air cooling system to reduce motor temperature to expand its lifespan.

3.Safety training: Strengthen the safety training of operators to ensure cutting work in a safe environment.

4.Environmental protection: Adopting environmentally friendly waste disposal methods, such as compressing and reusing or conducting harmless treatment.

The problems meat during the cutting process of composite materials cannot be ignored. By adopting methods such as professional equipment, optimizing cutting tools, strengthening safety training and environmental protection, we can effectively solve these problems, improve production efficiency and quality, while protecting the environment.

Post time: Apr-26-2024