What would you do if you encountered any of the following situations:

1.The customer wants to customize a small batch of products with a small budget.

2.Before the festival, the order volume suddenly increased, but it was not enough to add a large equipment or it will not be used after that.

3.The customer wants to buy a few samples before doing business.

4.Customers need a variety of customized products, but the quantity of each type is very small.

5.You want to start a new business but can’t afford a big machine at the beginning…..

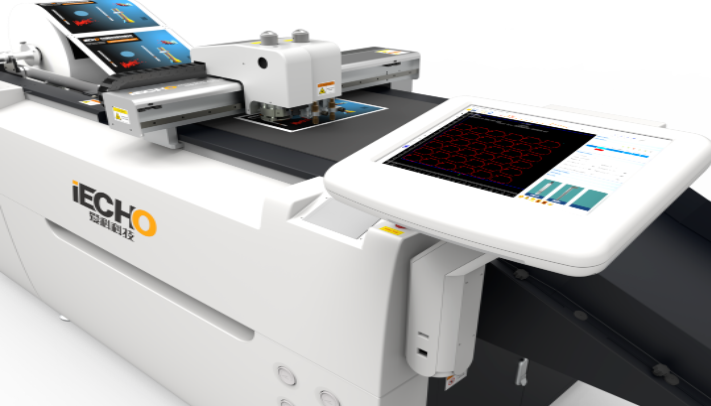

With the development of market, more and more customers need differentiated service and customized services. Rapid proofing, small batch customization, personalization, and differentiation have gradually become the mainstream of the market. The situation leads to the magnification of the shortcomings of traditional mass production, that is, the cost of a single production is high. To adapt to the market and meet the demands of small batch production, our company IECHO have launched the PK digital cutting machine. Which is designed for rapid proofing and small batch production.

Occupied only two square meters, PK digital cutting machine adopts fully automatic vacuum chuck and automatic lifting and feeding platform. Equipped with various of tools, it can quickly and precisely make through cutting, half cutting, creasing and marking. It is suitable for sample making and short-run customized production for Signs, printing and Packaging industries. It is a cost-effective smart equipment that meets all your creative processing.

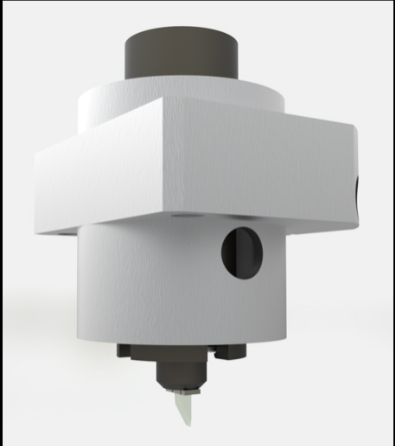

Graphic Tool

Total two graphic tools installed on PK cutting machine, mainly used in through cutting and half cut. 5 levels for tool pressing force control, maximum pressing force 4KG could realize cutting different material like paper, cardboard, stickers, vinyl etc. The minimum cutting circle diameter can reach 2mm.

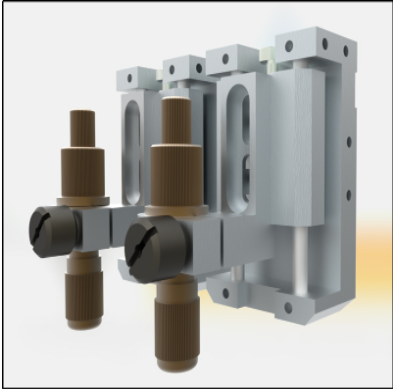

Electric Oscillating Tool

Knife cut material by the high-frequency vibration generated by the motor, which makes the maximum cutting thickness of PK can reach 6mm. It could be used in cutting Cardboard, gray board, corrugated board, PVC, EVA, foam etc.

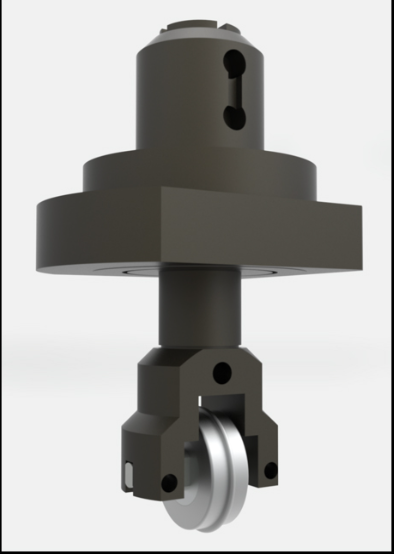

Creasing Tool

Maximum pressure 6KG, it can make crease on lots of material like corrugated board, card board, PVC, PP board etc.

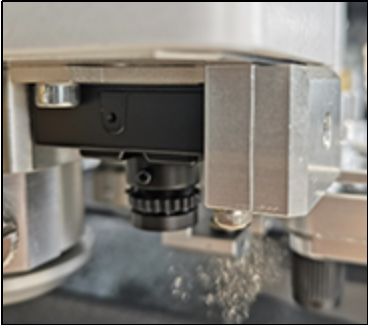

CCD Camera

With high-definition CCD camera, it can make automatic and accurate registration contour cutting of various printed materials, to avoid manual positioning and printing error.

QR Code Function

IECHO software supports QR code scanning to retrieve relevant cutting files saved in the computer to conduct cutting tasks, which meets the customers’ requirements for cutting different types of materials and patterns automatically and continuously, saving human labor and time.

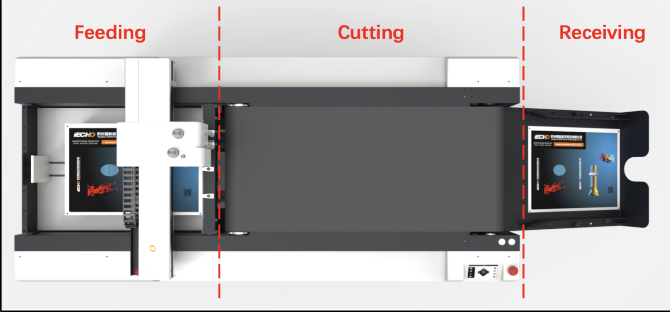

Machine is totally divided into three areas, Feeding, Cutting and Receiving. Vacuum connected with suction cups which is under the beam will absorb the material and transport it into cutting area. Felt covers on the aluminum platform forms the cutting table in cutting area, cutting head installing different cutting tools working on the material. After cutting, the felt with conveyor system will convey the product to the collection area. Entire process is fully automated and requires no human intervention.

Post time: Dec-28-2023