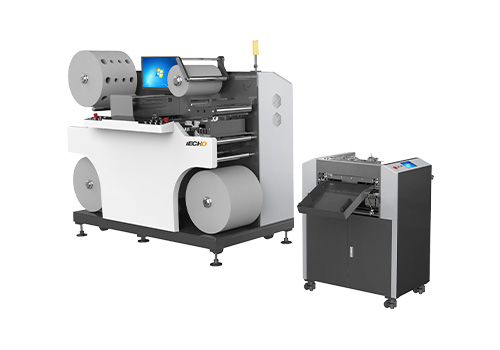

Digital printing and digital cutting, as important branches of modern printing technology, have shown many characteristics in development.

The label digital cutting technology is demonstrating its unique advantages with outstanding development . It is known for its efficiency and precision, bringing tremendous changes to the label manufacturing industry. In addition, digital printing also has the advantages of short printing cycles and low costs. At the same time, digital printing saves costs by eliminating the need for plate production and large-scale printing equipment operation.

Digital cutting, as a complementary technology to digital printing, plays an important role in the later processing of printed materials. It uses computer-controlled cutting tools for cutting and can perform cutting, edge cutting, and other operations on printed materials as needed, achieving efficient and accurate processing.

Faster cycle time

The development of digital label cutting has injected new vitality into the traditional label manufacturing industry. Traditional cutting methods are often limited by the capabilities of mechanical equipment and manual operations, which restrict production efficiency and accuracy. However, with its advanced automation technology, label digital cutting has completely changed this situation, achieving high-speed, efficient, and high-precision cutting, bringing unprecedented opportunities to the label manufacturing industry.

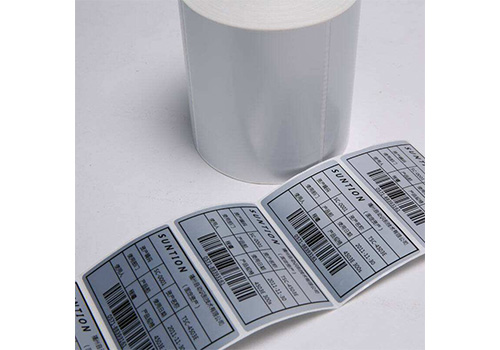

Customized and variable data cutting

Secondly, the superiority of tag digital cutting technology in its excellent flexibility and customization ability. Through digital control, label cutting machines can accurately cut labels of any shape according to different design requirements, making it easy to achieve. This personalized customization ability enables label manufacturers to meet the diverse needs of different customers and provide unique and personalized products.

Cost effectiveness

In addition, label digital cutting also brings cost saving advantages. Compared to traditional die cutting technology, digital cutting reduces material waste and labor costs. This efficient and cost saving feature enables label manufacturers to maintain competitiveness in fierce market competition and achieve better economic benefits.

Overall, the development of digital printing and digital cutting has brought technological innovation to the printing industry. They improve the quality and production efficiency of printed materials, while also meeting the needs of personalized customization. The development of these technologies will continue to drive the printing industry towards a more intelligent and efficient direction.

Post time: Jan-09-2024