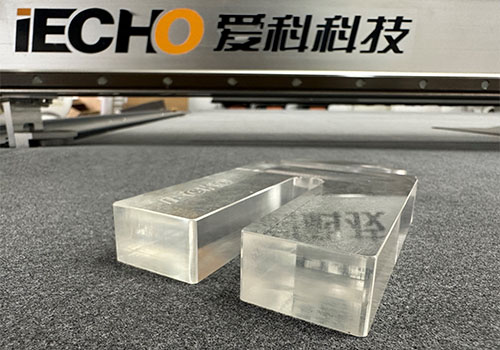

When cutting acrylic materials with extremely high hardness, we often face many challenges. However, IECHO has solved this problem with the excellent craftsmanship and advanced technology. Within two minutes, high-quality cutting can be completed, demonstrating the powerful strength of IECHO in the cutting field.

1、 AKI system and scanning, achieving efficient cutting

The IECHO TK4S machine is equipped with AKI system and scanning functions, greatly improving cutting efficiency. During the cutting process, the machine can automatically switch cutting tools and perform precise scanning, achieving automated cutting and scanning for different patterns and shapes without the need for manual intervention, greatly reducing labor costs.

2、 Full cutting, engraving, chamfer, and polishing, all four processes are completed simultaneously

As shown in the picture, this acrylic cutting product includes four processes: full cutting, engraving, chamfer, and polishing. During the cutting process, IECHO can automatically complete these processes based on preset files, making it easy to handle both large-scale cutting and fine engraving. Not only that, the machine can also polish the surface after cutting, ensuring cutting quality while also improving work efficiency.

3、 Simple operation, easy to complete cutting

Completing the cutting process is very simple. Simply import the required cutting files into the system, set various parameters, and start automatic cutting. Throughout the entire process, there is no need for manual intervention, greatly reducing the difficulty of operation. In addition, after the cutting is completed, the machine will automatically reset and stop cutting, preparing for the next operation.

With its advanced automation technology and excellent craftsmanship, IECHO has successfully solved the problem of acrylic cutting. Its efficient and high-quality cutting ability will undoubtedly play an important role in the future cutting industry. We look forward to IECHO Machinery demonstrating its strong capabilities in more fields.

Post time: Mar-01-2024