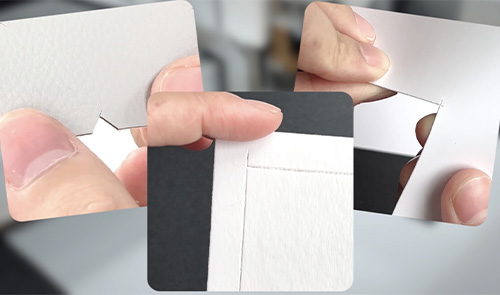

We often meet the problem of uneven samples while cutting ,which is called overcut. This situation not only directly affects the appearance and aesthetics of the product, but also has adverse effects on the subsequent sewing process.So, how should we take measures to effectively reduce the occurrence of such scenes.

Firstly, we need to understand that it is actually unlikely to completely avoid the phenomenon of overcut. However, we can significantly reduce the situation by selecting the appropriate cutting tool, setting up the knife compensation and optimizing the cutting method, so that the overcut phenomenon is in a acceptable range.

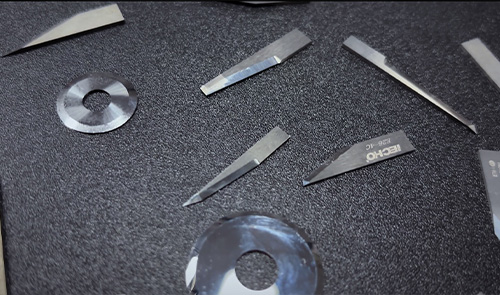

When choosing the cutting tool, we should try to use a blade with a smaller angle as much as possible,which means that the closer the angle between the blade and the cutting position is to the horizontal line, the more conducive it is to reducing overcut.This is because such blades can better fit the material surface during the cutting process, thereby reducing unnecessary cutting.

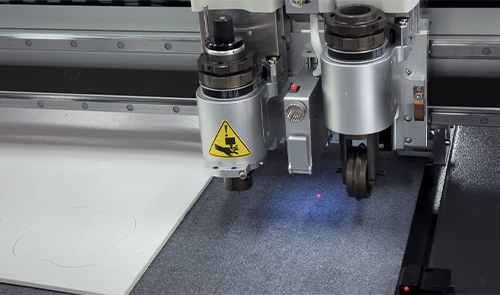

We can avoid part of the overcut phenomenon by setting up Knife-up and Knife-down compensation. This method is particularly effective in circular knife cutting. An experienced operator can control the cutting within 0.5mm, thereby improving the accuracy of cutting.

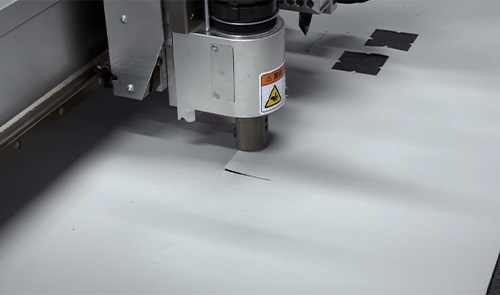

We can further reduce the phenomenon of overcut by optimizing the cutting method. This method is mainly applied to the advertising and printing industry. By utilizing the unique positioning point function of the advertising industry to perform backside cutting and ensure that the overcut phenomenon occurs on the back of the material. This can perfectly display the front of the material.

Through the use of the above three methods, we can effectively reduce the situation. However, it should be noted that sometimes the overcut phenomena is not exactly caused by the above reasons, or it may be caused by the X eccentric distance . Therefore, we need to judge and adjust according to the actual situation to ensure the accuracy of the cutting process

Post time: Jul-03-2024