The previous article talked about the introduction and development trends of the label industry, and this section will discuss the corresponding industry chain cutting machines.

With the increasing demand in the label market and the improvement of productivity and high-tech technology, the cutting machine market, as a midstream industry, has become increasingly active. At the same time, in order to meet the current market demand for high-precision, high-quality, and low-cost cutting, IECHO Cutting Machine has developed and updated a new generation of efficient label cutting machine—- RK330.

So how does the IECHO cutting machine RK330 perform efficient cutting?

At first,this equipment RK330 integrates the functions of laminating, cutting, slitting, winding, and waste discharge. Combined with web guiding system, CCD positioning, and intelligent multi-cutting head control technology, it can realize efficient roll-to-roll cutting and automatic continuous processing.

It’s completely liberates both hands, achieving continuous and precise intelligent cutting without manual labor, and saving labor costs.

At the same time, it also supports cold lamination, which is performed at the same time as cutting.It can achieve multifunctional implementation of one machine with multiple functions.

In addition, the machine uses digital die-cutting without the need to prepare a knife mold.It can cut any image, simply download the cutting file in advance from the computer, import the cutting image file before cutting to achieve intelligent cutting of any image.And not only increases flexibility but also saves costs.

The IECHO label cutting machine is also very inclusive in terms of material capacity. It supports a material width of 350mm, with a maximum label width of 330mm and has a very tolerant cutting length range.

It has multiple machine heads and blades at the same time.According to the number of labels, the system automatically assigns multiple machine heads to work at the same time, and can also work with a single machine head.This feature can achieve up to 4x efficiency.And achieve fast and accurate cutting effects while saving time for material replacement.

In addition, the IECHO label cutting machine can also be equipped with an automatic waste collection system as an option.The installation and operation are very simple, and it also has high efficiency in waste collection and can be carried out simultaneously with cutting.This option ensures the cleanliness of the environment and the recyclability of materials.

What materials can the IECHO label cutting machine cut?

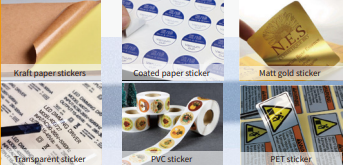

We all know that with the continuous development of the packaging industry, self-adhesive labels, as a type of label that does not need to be brushed, pasted, dipped in water, pollution-free, and time-saving, are in short supply.And the IECHO label cutting machine is suitable for any material’s adhesive, including but not limited to kraft paper, coated paper, matte gold, PVC, matte silver, etc.

Welcome to contact us

If you are looking for the right digital cutting machine, check out IECHO Digital Cutting Systems and visit https://www.iechocutter.com

Post time: Aug-31-2023