In the fast-evolving manufacturing industry, Medium-Density Fiberboard (MDF) is a go-to material for furniture production, interior decoration, and model making. Its versatility comes with a challenge: cutting MDF without causing edge chipping or burrs, especially for intricate right angles or curved designs. Selecting the right MDF cutting machine is crucial for achieving high-quality results and optimizing production efficiency. This guide explores key factors to consider when choosing a cutting machine for MDF, with insights into why IECHO Cutting Machines lead the industry.

Why cutting MDF is challenging

MDF, crafted from wood or plant fibers through hot pressing, has relatively loose internal structure. Traditional cutting methods often tear fibers, resulting in rough edges, chipping, or burrs. These imperfections compromise the finish quality, increase sanding time, and raise production costs. To overcome these issues, a cutting machine must deliver precision, power, and compatibility with MDF unique properties.

Key features to look for in an MDF Cutting Machine

Choosing the right machine involves evaluating several performance factors tailored to MDF characteristics. Here’s what to prioritize:

1. Powerful Cutting Performance

A machine with robust cutting power ensures clean, smooth cuts by efficiently severing MDF fibers. Insufficient power can lead to fiber tearing, causing edge chipping. IECHO cutting machines, equipped with a 1.8KW milling cutter, provide exceptional cutting force, minimizing imperfections and delivering flawless results.

2.High Cutting Precision

Precision is non-negotiable for MDF projects, especially when crafting sharp right angles or smooth curves. High-precision machines maintain accurate cutting lines, reducing errors. IECHO advanced transmission and control systems enable accurate positioning, ensuring every cut meets exact specifications.

3. Versatile Tool Compatibility

The right cutting tools make all the difference when cutting MDF materials. Milling cutters, due to its unique cutting method, can more effectively deal with the fiber structure of MDF materials and reduce chipping. IECHO offers a wide range of tool options, supporting various MDF thicknesses, hardness levels, and cutting needs, giving users flexibility and control.

4. Intelligent Cutting System

Modern MDF cutting demands smart technology. IECHO proprietary cutting system automatically adjusts speed and tool rotation based on material properties and design patterns. This ensures precise, efficient cuts, even for complex curves. Advanced motion control technology prevents path deviations, eliminating edge imperfections.

5. Equipment Stability and Durability

Cutting MDF is a demanding task that requires reliable equipment. A stable, durable machine minimizes downtime and maintenance costs while boosting productivity. IECHO cutting machines, built with high-strength frames and advanced manufacturing, excel under high-intensity workloads, ensuring long-term performance.

Why choosing IECHO Cutting Machines?

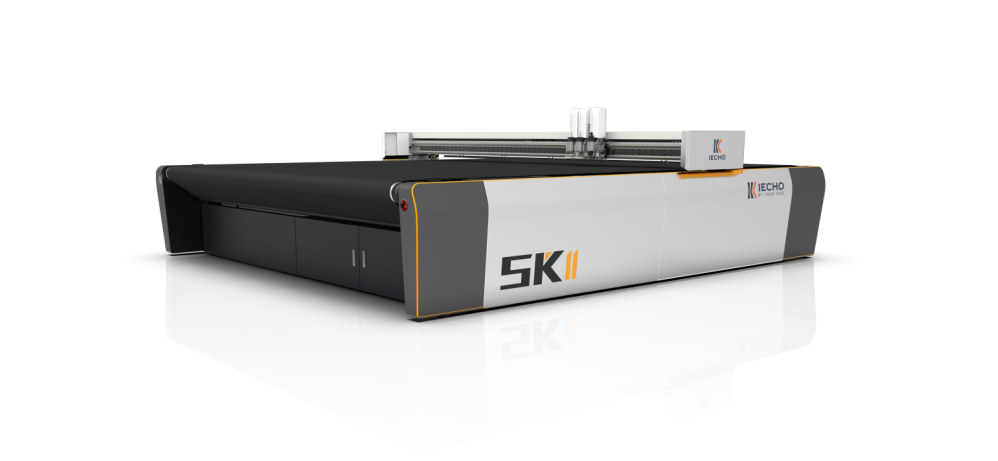

With over 30 years of expertise, IECHO Cutting Machines are synonymous with innovation and reliability. Designed for non-metal cutting, IECHO solutions set industry standards for precision and efficiency.

Selecting the best MDF cutting machine is critical for achieving perfect cuts, reducing waste, and enhancing productivity. Prioritize power, precision, tool compatibility, intelligent systems, and durability to tackle MDF unique challenges. With IECHO Cutting Machines, you gain access to industry-leading technology that delivers exceptional results every time.

Ready to elevate your MDF cutting process? Explore IECHO range of cutting machines and discover how they can transform your production line.

Post time: Apr-25-2025