Do you often meet customers sending unique and customized small-batch orders?Do you feel powerless and unable to find suitable cutting tools to meet the requirements of these orders?

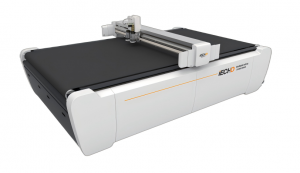

IECHO BK4 and PK4 digital cutting system as good partners for fully automated production line sampling and small-batch production in the packaging industry, has attracted much attention.

IECHO PK4 automatic intelligent cutting system adopts fully automatic vacuum chuck and automatic lifting and feeding platform, equipped with various of tools, it can quickly and precisely make through cutting, half cutting,creasing and marking.

PK4 is equipped with high frequency electronic oscillating knife and the max cutting thickness is 16mm,the max cutting speed is 1.2m/s and the cutting precision is ±0.1 mm.Combine intelligent cutting/creasing/drawing functions and meet all your creative processing demands

PK4 automatic intelligent cutting system with high-definition CCD camera, it realizes automatic and precise positioning of various materials,automatic contour cutting,solving problems of manual positioning and printing deformation.Optional touch screen computer and equipped with fully automatic feeding system.Scanning QR code allows quick reading of cutting tasks and makes the production more efficient

In addition,it supports common tools for increased flexibility. Compatible with IECHO CUT KISSCUT, EOT and other cutting tools and can meet the cutting needs of materials with higher density.

IECHO PK4 automatic intelligent cutting system is suitable for sample making and short-run customized production for Signs, Printing and Packaging industries, lt is a cost-effective smart equipment that meets all your creative processing.

BK4 high speed digital cutting system. with IECHO Automatic Camera Positioning System,AKI System and Dual Beams Cutting System.And update Intelligent IECHOMC Precision Motion Control.The maximum speed:1800mm/s and can be replaced at will and easily deal with the processing of different products in different industries.Intelligent conveyor System can intelligent control of material transmission realizes the coordinated work of cutting and collecting, realized continuous cutting for super-long marker, saving labor and improved production efficiency.The depth of cutting tool can be controlled accurately by the automatic knife initialization system.

BK4 equipped with high precision CCD camera can realizes automatic position on all kinds of materials,automatic camera registration cutting and solves problems of inaccurate manual position and print distortion.

In addition,the diversified cutting module configuration of this machine can be freely combined as needed and it can equip with various material unwinding devices ,satisfying the cutting requirements for different materials in different industries.BK4 with standard configured soundproof box can make your cutting environment quieter.

At the same time, it can also be equipped with IECHO devices such as IECHO Vision Scan Cutting System and robot arm to achieve more intelligent cutting and production.

Faced with the challenge of small-batch orders, the emergence of IECHO BK4 and PK4 provides a new solution for automated production in the packaging industry. Their high efficiency in cutting, high automation, flexibility, and quality assurance will bring about improvements in production efficiency, cost reduction, and product quality assurance for enterprises.

Post time: Aug-10-2024