IECHO fabric cutting machines integrate advanced technology and high-efficiency and designed specifically to meet the needs of the modern textile and home industry. They perform well in cutting fabrics, not only being able to handle fabrics of various materials and thicknesses, but also having significant advantages in cutting speed and precision.

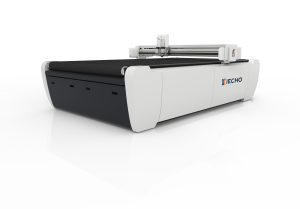

BK4 high speed digital cutting system

Advantages:

Cutting tools:

IECHO fabric cutting machines adopt two types of E-driven cutting tools, PRT and DRT, as well as POT A-driven cutting tools. PRT has a higher rotational speed, making it particularly suitable for cutting fabrics with higher hardness and thickness. POT is suitable for cutting a small amount of multi-layer fabrics. The advantages of these three types of cutting tools are that they are not easy to cause fabric brushes, and have fast cutting speed and high efficiency.

Machines

1.Software

IECHO fabric cutting machines are equipped with advanced lBrightCut and CutterServer software systems, which can realize automatic nesting and meet the cutting requirements of various special shapes.The intelligent nesting function of software can maximize material utilization and reduce waste.

2.Optional equipment

IECHO fabric cutting machines offer a variety of optional equipment, including Projection and Vision Scan Cutting System, to meet the special needs of different customers.

Vision Scan Cutting System:Using Vision Scan Cutting System can guide data cutting Just use a static photo and it has Large scale scanning to achieve dynamic continuous shooting.The system can live capture of graphics and contours in the feeding process.Once the feeding is completed, it will be continuously and accurate cutting immediately

Projection: IECHO advanced projection to achieve automatic recognition and digital projection of different cutting patterns. Each material corresponds to different cutting numbers, and precise pattern cutting is performed based on these numbers. At the same time, during the material picking up process, automatic recognition and digital projection are also achieved, and materials are collected according to different numbers.

The projection with IECHO software can achieve 1:1 automatic positioning, projecting cutting graphics proportionally onto the cutting table, accurately reading the material shape and defective areas, and achieving rapid automatic material layout, improving material utilization. At the same time, it is easy to operate and minimizes manual labor.

3.Punching tool

IECHO fabric cutting machines are equipped with various punching tools, which can meet the needs of special drilling and provide more possibilities for fabric processing.

4.Automatic feeding device

The design of the automatic feeding device enables the automation of the fabric feeding process, no manual intervention is needed, which greatly improves production efficiency and reduces labor intensity.

With the advanced cutting tool , intelligent software system, and diversified optional equipment, IECHO fabric cutting machine provide an efficient, precise, and automated cutting solution for the textile industry, greatly improving production efficiency and product quality.

TK4S Large format cutting system

Post time: Oct-18-2024