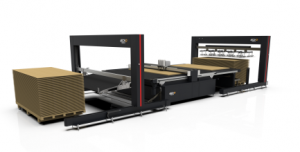

In today’s fast-paced production, IECHO TK4S feeding and collecting device completely replaces the traditional production mode with its innovative design and excellent performance. The device can achieve continuous processing 7-24 hours a day, and ensure the stable operation of the production line with its high degree of automation and reliability, ensuring the efficient operation of the production.

Efficient feeding design to meet various production needs

IECHO TK4S feeding and collecting device can be customized according to different materials and machine requirements. This feature enables the device to adapt to various production needs and easily cope with the customization of materials of various sizes. This flexible loading design greatly improves the continuity and efficiency of the production.

High automation, reducing manual dependence

IECHO TK4S feeding and collecting device has a high degree of automation and is easy to operate. The device can independently complete the entire process of loading, cutting, and collecting, greatly reducing the reliance on manual labor. This not only reduces the risks and costs caused by human operating errors, but also saves human resources for the company and improves production efficiency.

Precision sensing and cutting system ensures machining accuracy

The TK4S large format cutting system can be customized in different sizes and has a flexible working area.

And it can equip with IECHO AKI System,and the depth of cutting tool can be controlled accurately by the automatic knife initialization system.

TK4S equipped with high precision CCD camera, the system realizes automatic position on all kinds of materials,automatic camera registration cutting,and solves problems of inaccurate manual position and print distortion,thus to complete procession task easily and precisely.

In addition,the continuous cutting system with IECHO feeding and collecting device , to achieve feeding,cutting and picking up the samples at the same time.It totally saves the labor cost and improves the efficiency significantly.

In the cutting field, the TK4S large format cutting system is matched with diversified cutting tools of three heads,in order to meet different industrial cutting requirements,the cutting head can be flexibly chosen from the standard head,punching head and the milling head.While meeting high precision requirements,the cutting speed can reach up to 1.5m/s,which is 4-6 times of traditional manual way,greatly shortened working hours and improved production efficiency.

Continuous processing 7-24 hours a day

What is more worth mentioning is that the device can achieve continuous processing 24 hours a day and 7-days a week. This means that the production line can run stably at any time and in any environment without manual intervention. This feature greatly improves the continuity and stability of the production line and reduces the operating costs of the enterprise.

IECHO TK4S feeding and collecting device has brought new changes to production with its innovative design and excellent performance. Its flexible loading design, simple operation method and precise and fast cutting system have injected new vitality into production.

Post time: Nov-15-2024