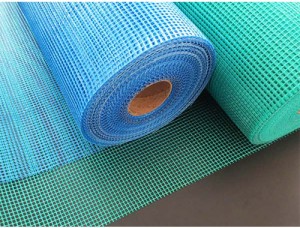

With the global environmental protection policies becoming more stringent and the acceleration of the intelligent transformation of the manufacturing industry, the cutting processes of traditional composite materials such as fiberglass Fabric are undergoing profound changes. As an innovative benchmark in the field of composite material processing, IECHO Cutting Machine, with its independently developed intelligent cutting system, provides efficient and environmentally friendly solutions for fields such as wind power, aerospace, and automotive manufacturing, propelling the industrial chain towards green and sustainable development.

With its high precision, high efficiency, and modular design, BK4 has successfully addressed pain points in traditional cutting processes, such as a high rejection rate and strong dependence on manual labor. It helps customers achieve the dual goals of cost reduction, efficiency improvement, and green production.

IECHO BK4 is a high – speed system capable of cutting few multi – layers. It can automatically and accurately complete processes such as full – cutting, half – cutting, engraving, V – grooving, creasing, and marking. This equipment integrates the functions of automatic feeding, cutting, and unloading of fiberglass coils, effectively reducing dependence on manual labor and significantly improving production efficiency. Moreover, it features a small cutting pattern, making it suitable for small – batch production and sample – making of fiberglass cloth.

The BK4 cutting system can be optionally configured with multiple tool heads, supporting the cutting of composite materials such as fiberglass fabric, fiberglass wool, prepreg, carbon fiber fabric, and ceramic fiber. By selecting or assembling different tool heads, the system effortlessly adapts to diverse material cutting requirements, offering significant convenience for enterprises.

In terms of cost control, it effectively replaces manual cutting, substantially reducing labor costs. Cutting materials like fiberglass fabric and ceramic fiber typically incurs high labor expenses, whereas the equipment ensures stable and efficient task execution. Additionally, the system achieves a lower rejection rate compared to manual operations and enables precise calculation of material utilization rates, helping manufacturers better control material costs.

Currently, IECHO, a global provider of intelligent cutting integrated solutions for the non-metallic industry, has expanded its product reach to over 100 countries and regions across Asia, Europe, Africa, North America, South America, and Oceania. Its robust R&D team and comprehensive after-sales service system provide customers with full-spectrum support.

With the widespread adoption of IECHO’s BK4 intelligent fiberglass fabric cutting equipment, the fiberglass processing industry is advancing toward greater intelligence, efficiency, and sustainability. Looking ahead, IECHO will continue to uphold its commitment to technological innovation, delivering cutting-edge intelligent cutting solutions to the non-metallic industry and empowering industry users to embark on a new chapter in intelligent cutting.

Post time: Feb-27-2025