1.Latest Trends and Market Analysis of the Label Industry

Intelligence and digitization drive innovation in label management:

As corporate demands shift toward personalization and customization, the label industry is accelerating its transformation toward intelligence and digitization. The global label management system market is expected to achieve significant growth in 2025, especially in the fields of e-commerce, logistics, and consumer goods. Intelligent label management systems significantly improve supply chain efficiency and customer experience through automated data tracking and dynamic content updates. In addition, tightening environmental regulations have driven demand for labels made of degradable materials, further stimulating technological innovation in the industry.

Market growth and potential in sub-segments:

According to the 2025 Global Label Management System Market Report, the compound annual growth rate (CAGR) of the label software market is expected to reach 8.5%. At the same time, the demand for high-precision and highly customized labels continues to rise, driving the upgrade of label printing technology and cutting equipment.

2.Current Status and Advantages of IECHO LCT Laser Cutter)

IECHO LCT350 laser die-cutting machine, modular design of the whole machine and adopt servo motor and encoder closed-loop motion.The core laser module adopts an imported 300W illuminant .Paired with IECHO’s independently developed operating software, making it easy and simple to operate with just one-click. (Simple operation, easy to get started)

The max cutting width of the machine is 350MM,and the max outer diameter is 700MM,and it is a high-performance digital laser processing platform integrating automatic feeding, automatic deviation correction, laser flying cutting, and automatic waste removal and the laser cutting speed of 8 m/s.

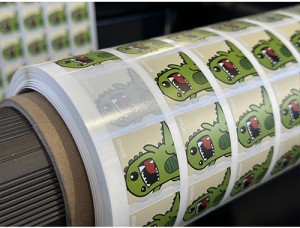

The platform is suitable for different processing modes such as roll-to-roll, roll-to-sheet, sheet-to-sheet, etc. It also supports synchronous film covering, one-click positioning, digital image changing, multi process cutting, slitting, winding, waste discharge and sheet breaking functions.

It is mainly used in materials such as sticker, PP, PVC, cardboard and coated paper,etc. The platform does not require cutting die, and uses electronic files import to cut, providing a better and faster solution for small orders and shorter lead times.

3. Market application and competitive advantages

Precisely adapted to the needs of the label industry: LCT models support ultra-thin material cutting (minimum thickness 0.1mm), meeting the label industry’s dual requirements for precision and speed.

Energy saving and environmental protection: Compared with traditional mechanical cutting, laser technology reduces energy consumption by 30% and has no tool loss, which is in line with the global carbon reduction trend.

Flexibility and compatibility: The equipment can be integrated with an ERP system to achieve real-time monitoring of production data and assist in the intelligent transformation of enterprises.

According to the 2024 Laser Cutting Industry Report, the share of IECHO’s LCT series in the Asian market has grown to 22%, and the technological maturity and after-sales service have become key factors in customer selection.

Post time: Feb-18-2025