In recent years, driven by growing environmental awareness and industrial automation, PP Plate sheet has emerged as a new favorite in logistics, food, electronics, and other sectors, gradually replacing traditional packaging materials. As a global leader in intelligent cutting solutions for non-metal industries, IECHO’s BK4, SK2, TK4S series cutting machines have been widely adopted in PP Plate sheet processing due to the features of high precision, efficiency, and intelligence .

PP Plate sheet: A Sustainable and High-Performance Packaging Choice

PP Plate sheet is extruded from copolymer-grade polypropylene in one step, offering lightweight, impact resistance, waterproofing, corrosion resistance, and extreme temperature tolerance (-17°C to 167°C). Its unique hollow structure provides excellent compressive strength and cushioning performance while supporting reuse and recycling, aligning with the green economy trend. It is now widely used in fresh cold chain transportation (e.g., fruits, vegetables, aquatic products) and protective packaging for precision products (e.g., electronic components, medical devices). For example, in logistics, PP corrugated turnover boxes reduce cargo damage in humid environments, while in advertising, its rich colors and easy processing make it an ideal material for outdoor display panels.

IECHO Cutting Machines: Reshaping Processing Standards with Technical Breakthroughs

Addressing PP Plate sheet’s unique physical properties, IECHO’s BK4, SK2, and TK4S series cutting machines deliver efficient and precise processing through core innovations:

Intelligent Cutting System:

Equipped with IECHO’s proprietary Cutterserver control center, these machines seamlessly integrate with CAD software, enabling automatic parsing and path planning for complex graphics. High-precision servo motors and an electronic induction automatic tool alignment system ensure cutting depth control accuracy of 0.01mm, supporting full-cut, half-cut, and V-groove processes.

High-Speed and Stability:

The TK4S series features a high-strength welded frame and aerospace aluminum honeycomb tabletop, combined with X-axis dual-motor balanced transmission technology. This ensures stability during ultra-wide format processing, preventing material deformation and maintaining smooth cutting arcs and precise dimensions. It achieves cutting speeds 4–6 times faster than traditional manual methods while sustaining multifunctional stability.

Diversified Functionality:

Modular toolhead configurations allow flexible integration of standard cutting heads, punching heads, and routing heads to meet customized needs across industries. For instance, in electronics packaging, electrostatic-treated PP Plate sheets enable precise slotting and marking. In automotive interiors, continuous cutting systems automate long-layout production, reducing labor costs.

User-friendly ergonomics and operation:

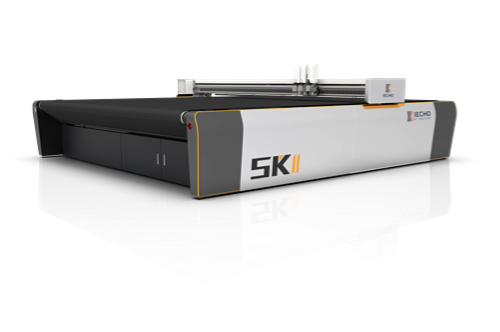

IECHO SKII High-precision multi-industry flexible material cutting system adopts One-time Modular Steel Frame.The frame of the fuselage is made of high-quality carbon structural steel, which is formed at one time by a large five-axis gantry milling machine and has high strength, corrosion resistance and strong toughness make the whole equipment more stable while ensuring the accuracy of the equipment.The SKII system also features user-friendly ergonomics and the intuitive user interface and reasonable layout design ensure comfort and convenience during operation, thereby improving work efficiency.

With the in-depth integration of intelligent manufacturing and green economy, the coordinated development of PP Plate sheets and intelligent cutting technology is injecting new impetus into the transformation and upgrading of the packaging and logistics industry. A relevant person in charge of IECHO said that in the future, it will continue to increase R&D investment, promote the in-depth integration of equipment intelligence and material innovation, and help global customers seize the initiative in competition.

Post time: Mar-21-2025