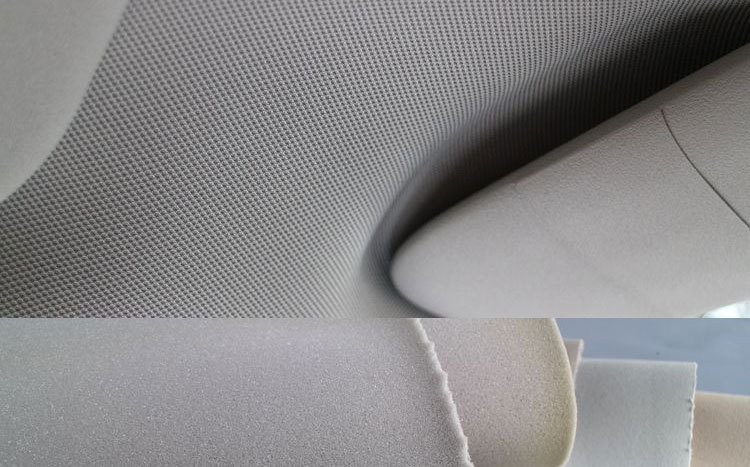

PU composite sponge has been widely used in automotive interior production due to its excellent cushioning, sound absorption, and comfort characteristics. So how to choose a cost-effective digital cutting machine has become a hot topic in the industry.

1、PU composite sponge cutting has obvious disadvantages:

1)Rough edges can easily reduce quality

PU composite sponge is soft and elastic, and is easily deformed by the extrusion of the tool during cutting. If the cutting speed and force of ordinary tools are not well controlled, the edge of the sponge will be jagged or wavy, which will seriously affect the appearance of the interior and reduce product quality. This problem is particularly prominent in the field of automotive interiors, which have strict requirements on appearance.

2)Poor dimensional accuracy

Automotive interior parts require extremely high dimensional accuracy, and each part must be accurately matched and installed. When PU composite sponge is cut, the actual size often deviates from the designed size due to the influence of material elasticity, cutting equipment accuracy and process.

3)Dust and debris pollute the environment

Cutting PU composite sponge will generate a lot of dust and debris. It is not only polluting the environment and endangering the health of operators, but also may be embedded in the sponge, reducing product quality, causing failures in subsequent assembly, and increasing the defective rate.

2、How to choose a cost-effective digital cutting machine?

1)EOT has significant advantages in PU composite sponge cutting.

The high-frequency vibration of the tool can reduce cutting resistance, reduce material deformation, and make the cutting edge smooth with an accuracy of ±0.1mm.

IECHO BK4 high-speed digital cutting system, matched with intelligent tool management system, can adjust the vibration frequency and cutting speed according to the thickness and hardness of the sponge, greatly improving efficiency and quality.

2)Equipment stability is important

Mechanical structure is the foundation of equipment stability. IECHO BK4 Ultra-high Strength Integrated Frame,12mm steel frame with qualified connection technology, the machine body frame weighs 600KG.

Strength increased by 30%, reliable and durable, ensuring the smooth operation of the cutting platform, long-term use without deformation, and ensuring cutting accuracy.

3)The electrical system is also critical

The high-quality servo motor, driver and control system are selected, which have fast response and precise control, and can ensure stable cutting. IECHO’s servo drive system, combined with the independently developed intelligent control system, can achieve high-speed and high-precision cutting.

4)After-sales service

Technical support is an important part of after-sales guarantee. IECHO‘s after-sales service team provides 24-hour professional service. Through a combination of online and offline modes, it maximizes efficiency in responding to customers’ technical consultation and fault repair needs, and reduces production delay losses.

5)The timeliness of spare parts supply directly affects the equipment maintenance cycle.

IECHO has sufficient spare parts inventory and a complete supply system to avoid long equipment downtime due to spare parts shortage. Timely and fast delivery of commonly used spare parts ensures stable operation of equipment and improves cost-effectiveness.

In the task of cutting PU composite sponge for automotive interiors, IECHO has always adhered to the service concept of “BY YOUR SIDE” with the profound technical accumulation and innovative spirit, and has helped enterprises overcome difficulties in all aspects. Choosing IECHO means choosing professionalism and efficiency, achieving a perfect balance between production efficiency, product quality and cost control, and opening a new chapter in the production of automotive interiors.

Post time: Mar-14-2025