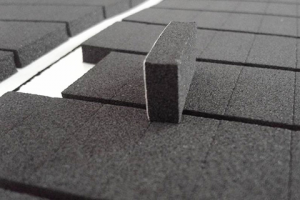

PE foam , an exceptional polymer material renowned for its unique physical properties, plays pivotal roles across diverse industrial applications.

Addressing critical cutting requirements for PE foam, IECHO Cutting Machine emerges as an industry-leading solution through innovative blade technology upgrades, notably implementing oscillating knife systems that effectively resolve conventional processing limitations:

Limitations of Traditional Cutting Processes:

1.Precision Deficiencies Causing Material Waste

2.Productivity Constraints

Manual operations limit daily output to 200-300 sheets.

Complex contours require 2-3X longer processing due to multi-stage positioning

Incompatible with bulk order requirements

3.Inflexible Production Adaptation

Mold dependency increases marginal costs by ≥50% for small-batch orders.

Pattern modifications necessitate mold replacement.

IECHO Cutting Machine’s Technological Superiority

1.High-Frequency Oscillation Cutting Principle.

High Electronic Oscillating reduces the contact surface between the cutting edge and the material during cutting, thereby reducing vertical pressure and eliminating material compression deformation.

2.Electronic Oscillating Knife for cutting soft and medium density materials, available with1mm stroke.Paired with a wide variety of blades, it can handle the cutting of the vast majority of flexible materials.

3.IECHO Automatic Camera Positioning System:Equipped with high precision CCD camera, the system realizes automatic position on all kinds of materials,automatic camera registration cutting,and solves problems of inaccurate manual position and print distortion,thus to complete procession task easily and precisely.

4.AKl System:The depth of cutting tool can be controlled accurately by the automatic knife initialization system.

5.IECHO motion control system,CUTTERSERVER is the center of cutting and controlling,enables smooth cutting circles and perfect cutting curves.

6.Full-Thickness Processing Capability.

Cutting range: 3mm acoustic foams to 150mm heavy-duty packaging materials.

Blade lifespan extends to 200,000 linear meters/cutting edge.Maintenance costs reduced by 40%.

7.Digital Production Management.

AI-powered nesting software optimizes material utilization.Automatic tool path generation improves yield by 15-25%.Cloud-based process monitoring enables real-time optimization.

IECHO’s cutting technology redefines PE foam processing value chains through integrated smart sensors, algorithmic optimization, and process innovation.This cutting-edge solution establishes new industry benchmarks for intelligent manufacturing in polymer material processing.

Post time: Feb-27-2025