As a high -performance material, carbon fiber has been widely used in the fields of aerospace, automobile manufacturing, and sporting goods in recent years. Its unique high-strength, low density and excellent corrosion resistance make it the first choice for many high-end manufacturing fields. However, the processing and cutting of carbon fiber are relatively complicated, and traditional cutting methods often have problems such as low efficiency, low accuracy, and serious waste of materials. It requires more professional technology and equipment to ensure that its performance is not damaged.

Common materials: various flexible materials such as carbon fiber, prepreg, glass fiber, aramid fiber, etc.

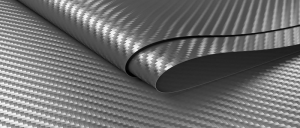

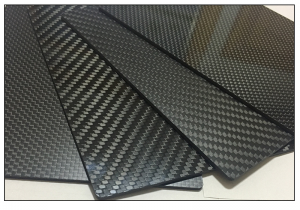

Carbon fiber: It is a new type of fiber material with high strength and high modulus fibers containing more than 95% carbon. It has the characteristics of corrosion resistance and high film content, and it is an important material in terms of defense and civilian use.

Glass fiber: It is a high-performance inorganic non-metallic material with a wide variety of types. Its advantages include good insulation, strong heat resistance, good corrosiveness, and high mechanical strength. However, its disadvantages include brittleness and poor corrosiveness. It is commonly used as a reinforcing material, electrical insulation material, thermal insulation material, and circuit substrate in composite materials, and is widely used in various fields of the national economy.

Aramid fiber composite material is one of the three high-performance materials, which has a significant impact on national defense and key industrial projects such as airplanes and high-speed rail. It is used in military applications such as aircraft and ships, and in civilian applications such as aerospace, high-performance components for automobiles, rail transit, nuclear power, insulation materials for power grid engineering, building insulation materials, circuit boards, printing, and medical materials.

What are the defects of the existing cutting methods for composite materials, such as grinding tools, stamping, laser machines, etc. In traditional cutting, a large amount of heat is easily generated, leading to thermal damage to the material surface and damage to the internal structure. Although laser cutting has high precision, it is costly and may produce harmful smoke and gas during the cutting process, posing a threat to the health of operators and the environment.

The advantages of IECHO digital intelligent cutting equipment in this industry:

1. Replace manual labor, improve factory environment, and enhance product competitiveness

2. Save time and effort, ensure cutting accuracy

3. Automatic loading and unloading, uninterrupted operation, smoke-free and dust-free to replace 3-5 manual workers

4. High precision, fast speed, not limited by cutting patterns, can cut any shape and pattern

5. Automated cutting makes work easier and more efficient.

Applicable cutting tools:

EOT:By controlling the high-frequency vibration of the blade up and down through a servo motor, the cutting effect is excellent and suitable for carbon fiber materials. High precision cutting to enhance product competitiveness.

PRT:Drive the cutting material at high speed through the motor, cutting materials can be achieved without hanging wires or burrs on the cutting edge, making it suitable for cutting various types of woven materials. Solve the problems of low efficiency and harm to human body caused by manual cutting.

POT:By controlling the gas to achieve reciprocating cutting, the kinetic energy is greater and it is suitable for cutting a few of multi-layers.

UCT:The UCT is suited for cutting through and scoring a wide range of materials with fast speed. Comparing with the other tools, UCT is the most cost-effective tool. It has three types of blade holders for different blades.

Post time: Aug-29-2024