Market and classification of genuine leather:

With the improvement of living standards, consumers are pursuing a higher quality of life, which drives the growth of leather furniture market demand. The mid-to-high-end market has stricter requirements on furniture materials, comfort and durability.

Genuine leather materials are divided into full-grain leather and trimmed leather. Full-grain leather retains its natural texture, with a soft touch and high durability. Trimmed leather is processed to have a uniform appearance and is less durable. Common classifications of genuine leather include top-grain leather, which has excellent texture, good elasticity, and strong wear resistance; Split-grain leather, which has a slightly inferior texture and high cost-effectiveness; and imitation leather, which looks and feels similar to genuine leather, but has different characteristics and is used for low-priced furniture.

In the production process of genuine leather furniture, shaping and cutting are particularly critical. Usually, the production of high-quality furniture combines traditional hand-shaping with modern cutting technology to ensure that the texture and quality of the leather are best displayed.

With the expansion of the leather furniture market, traditional manual cutting can no longer meet the market needs. How to choose a leather cutting machine? What are the advantages of IECHO’s digital leather solution?

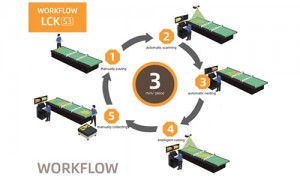

1.Single -person workflow

It takes only 3 minutes to cut a piece of leather and can complete 10,000 feet per day with single -person.

2.Automation

Leather contour acquisition system

Leather contour acquisition system can quickly collect contour data of the entire leather ( area,circumference, flaws, leather level, etc)Auto recognition flaws.The leather defects and areas can be classified according to the customer’s calibration.

Nesting

You can use leather automatic nesting system to complete the nest of a whole piece of leather in 30-60s.Increased leather utilization by 2%-5%( The data is subject to actual measurement)Automatic nesting according to the sample level.Different level of defects can be used flexibly according to customer requests to further improve the utilization of leather.

Order management system

LCKS order management system runs through each link of digital production, flexible and convenient management system, monitor the whole assembly line in time, and each link can be modified in the production process.Flexible operation, intelligent management, convenient and efficient system, greatly saved the time spent by manually orders.

Assembly line platform

LCKS cutting assembly line including the whole process of leather inspection -scanning -nesting – cutting- collecting.Continuous completion on its working platform, eliminates all traditional manual operations. Full digital and intelligent operation maximizes cutting efficiency.

3.Cutting advantages

LCKS equipped with IECHO all-new generation professional leather high-frequency oscillating tool,25000 rpm ultra-high oscillating frequency can cut the material at high speed and accuracy.

Optimize the beam to increase the cutting efficiency.

Post time: Dec-27-2024