Nylon is widely used in various clothing products, such as sportswear, casual clothes, pants, skirts, shirts, jackets, etc., due to its durability and wear resistance, as well as good elasticity. However, traditional cutting methods are often limited and cannot meet the increasingly diverse needs.

What problems will be encountered in cutting the nylon synthetic polymer?

Nylon synthetic polymers are prone to some problems during cutting. These problems may have a negative impact on the performance of the material and the quality of the final product. The following are some common problems and their reasons:

Firstly, nylon materials are prone to produce edges and cracks when cutting, as their molecular structure is prone to uneven deformation when subjected to external forces.

Secondly, nylon has a high coefficient of thermal expansion, and the heat generated during the cutting process may cause the material to deform and affect the cutting accuracy. In addition, nylon is also prone to static electricity during cutting, adsorbing dust and debris, affecting the neatness and subsequent processing of the cutting surface. In order to overcome these problems, it is usually important to choose the appropriate cutting machine, tools, adjustment of cutting speed and parameters.

Machine selection:

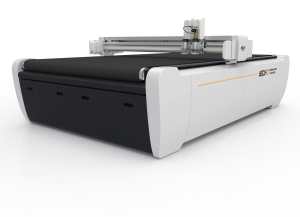

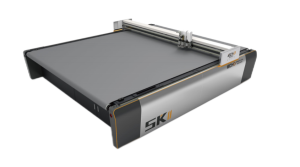

In terms of machine selection, you can choose to consider the BK series, TK series, and SK series from IECHO. They are matched with diversified cutting tools of three heads,in order to meet different industrial cutting requirements,the cutting head can be flexibly chosen from the standard head,punching head and the milling head.While meeting high precision requirements,the cutting speed can reach up to 4-6 times of traditional manual way,greatly shortened working hours and improved production efficiency.

And it can be customized in different sizes and has a flexible working area.And it can equip with IECHO AKI System,and the depth of cutting tool can be controlled accurately by the automatic knife initialization system.They are equipped with high precision CCD camera, the system realizes automatic position on all kinds of materials,automatic camera registration cutting,and solves problems of inaccurate manual position and print distortion,thus to complete procession task easily and precisely.

Tool selection:

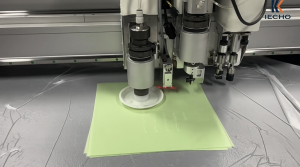

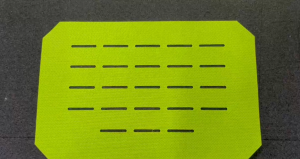

In the figure, for single-layer nylon cutting, PRT has a faster speed and can quickly cut larger and more obvious graphic data. However, due to its inherent cutting speed, PRT has limitations in processing small graphic data and can be combined with POT to complete cutting.POT can cut small graphics in detail, especially suitable for a small amount of multi-ply cutting.

Cutting parameters:

For this material, in terms of cutting parameter settings, the cutting speed of POT is often set to 0.05M/s, while PRT is set to 0.6M/s. The reasonable combination of these two can meet the needs of large-scale production and also cope with small-scale and refined cutting tasks. Additionally, set relevant parameters based on the specific material characteristics.

If you are looking for a nylon cutting machine that can meet all your needs, you can contact us. You will have an unparalleled cutting experience and excellent cutting results.

Post time: Aug-26-2024