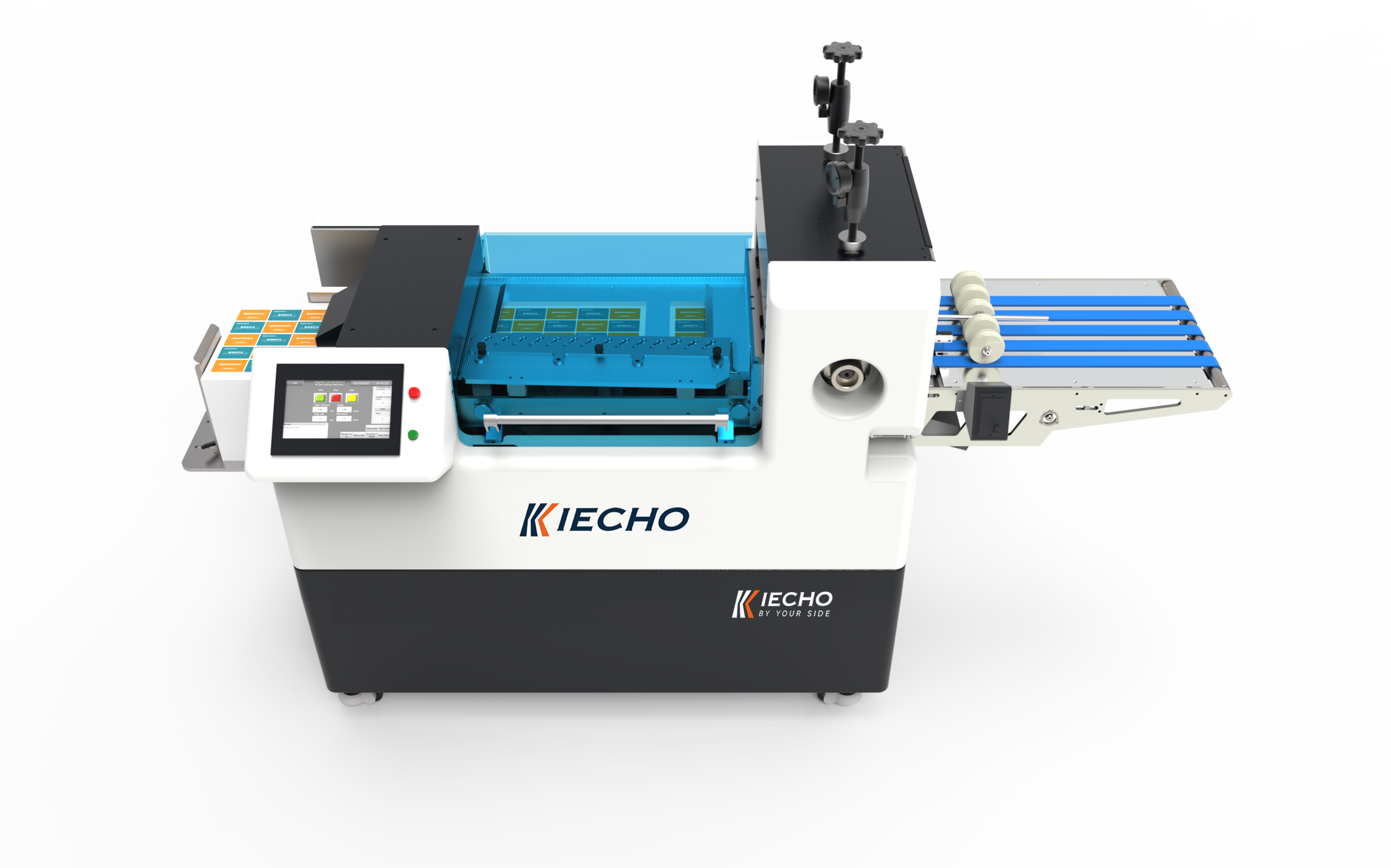

MCT Rotary die cutter

feature

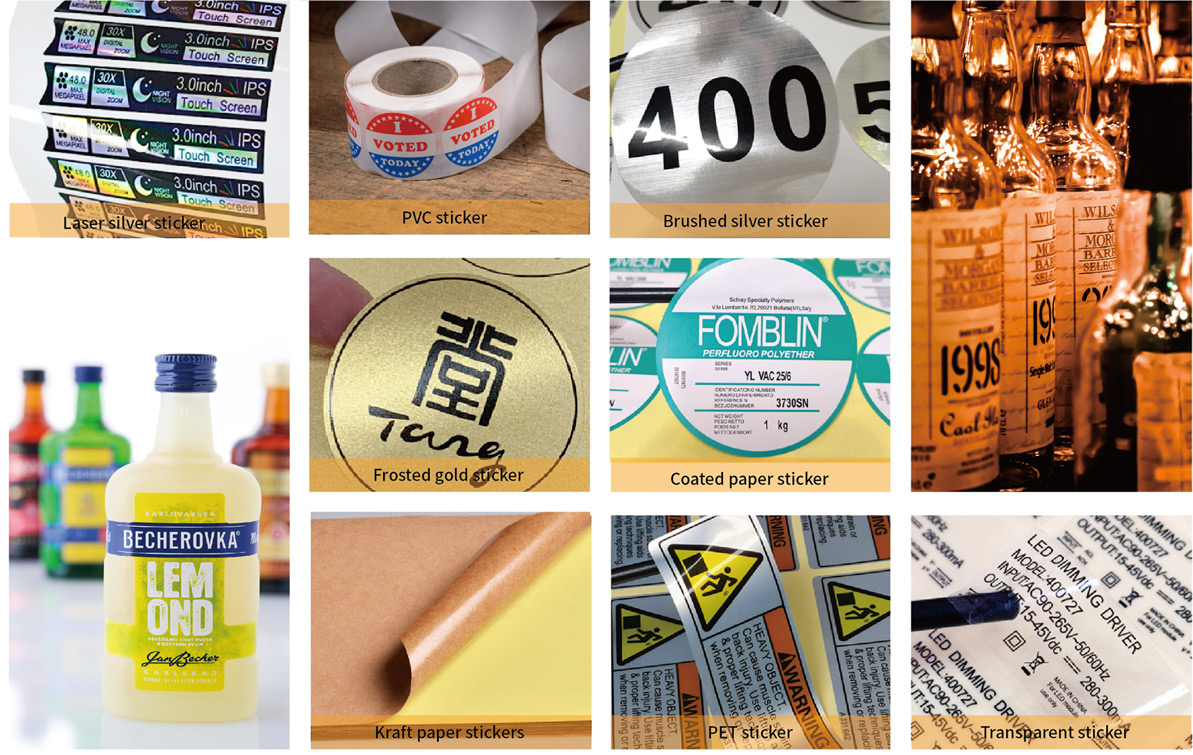

application

Widely used in self-adhesive stickers, wine labels, clothing tags, playing cards and other products in printing and packaging, clothing, electronics and other industries.

parameter

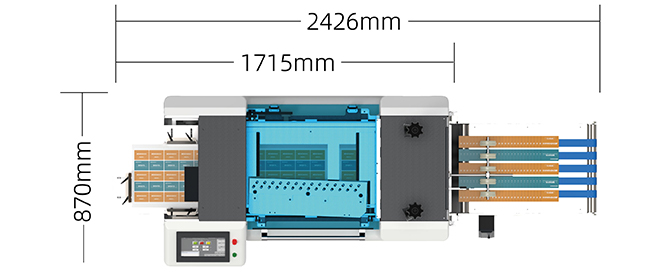

| Size(mm) | 2420mm ×840mm × 1650mm |

| Weight (KG) | 1000kg |

| Maximum paper size(mm) | 508mm×355mm |

| Minimum paper size(mm) | 280mm x210mm |

| Maximum die plate size(mm) | 350mm ×500mm |

| Minimum die plate size(mm) | 280mm ×210mm |

| Die plate thickness(mm) | 0.96mm |

| Die cutting accuracy(mm) | ≤0.2mm |

| Maximum die cutting speed | 5000 sheets/hour |

| Maximum indentation thickness(mm) | 0.2mm |

| Paper weight(g) | 70-400g |

| Loading table capacity (sheets) | 1200sheets |

| Loading table capacity (Thickness/mm) | 250mm |

| Minimum width of waste discharge(mm) | 4mm |

| Rated voltage(v) | 220v |

| Power rating(kw) | 6.5kw |

| Mould Type | Rotary die |

| Atmospheric pressure(Mpa) | 0.6Mpa |

system

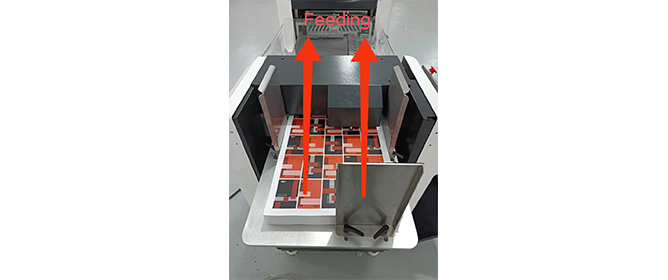

automatic feeding system

The paper is fed by the tray lifting method, and then the paper is peeled off from top to bottom by the vacuum suction cup belt, and the paper is sucked and transported to the automatic deviation correction conveyor line.

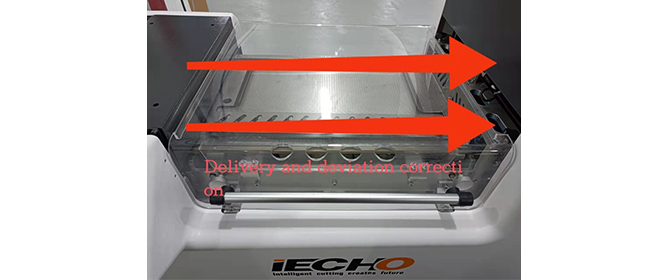

Correction system

At the bottom of the automatic deviation correction conveyor line, the conveyor belt is installed at a certain deviation angle. The deviation angle conveyor belt conveys the paper sheet and advances all the way. The upper side of the driving belt can be adjusted automatically. The balls exert pressure to increase the friction between the belt and the paper, so that the paper can be driven forward.

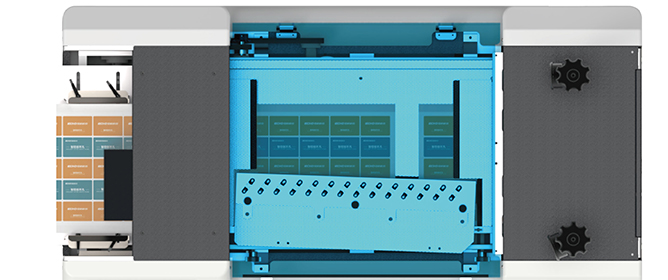

Die Cutting System

The desired pattern shape is die-cut by the high-speed rotating flexible die-cutting knife of the magnetic roller

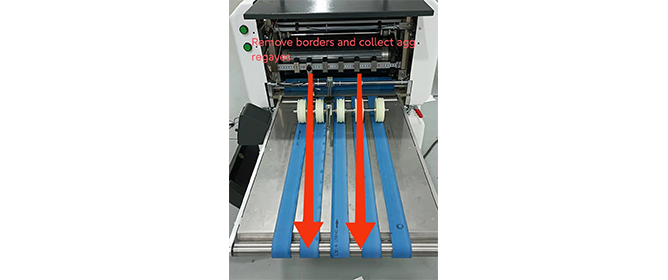

waste rejection system

After the paper is rolled and cut, it will pass through the waste paper rejection device. The device has the function of rejecting waste paper, and the width of rejecting waste paper can be adjusted according to the width of the pattern.

Material conveying system

After the waste paper is removed, the cut sheets are formed into groups through the rear-stage material grouping conveyor line. After the group is formed, the cut sheets are manually removed from the conveyor line to complete the entire automatic cutting system.