Ka tsoelo-pele e tsoelang pele ea theknoloji, mechine ea ho itšeha ea laser e 'nile ea sebelisoa haholo tlhahiso ea indasteri e le lisebelisoa tse sebetsang hantle le tse nepahetseng. Kajeno, ke tla u nka ho utloisisa boemo ba hona joale le tataiso nakong e tlang ntshetsopele ya indasteri laser itšeha mochini.

Ntlha ea pele, tlhokahalo ea 'maraka ea mechine ea ho itšeha ea laser e ntse e hōla. Ka nts'etsopele ea indasteri ea tlhahiso, litlhoko tsa ts'ebetso ea ts'ebetso le boleng li ntse li phahama le ho feta, e leng se qobellang mechine ea laser ho itšeha ho tsoela pele ho ntlafatsa le ho ntlafatsa ho finyella tlhokahalo ea 'maraka. Ho ea ka lipalo-palo, thekiso ea mechine ea ho itšeha ka laser e eketsehile butle-butle lilemong tsa morao tjena, haholo-holo lits'ebetsong tse kang ho etsa likoloi, lifofane, elektroniki le masimo a mang. Sena se bontša litebello tse atileng tsa mechine laser itšeha 'marakeng.

Tabeng ya bobedi, thekenoloji popontshwa ya laser ho itšeha mechine e boetse e tsoela pele ho khanna ntshetsopele ya indasteri. Ka tsoelo-pele e tsoelang pele ea thekenoloji, theknoloji ea mechine ea ho itšeha ka laser e lula e ntlafatsoa . Ka mohlala,

mehloli ea laser e tsoetseng pele le litsamaiso tsa optical li sebelisetsoa ho etsa hore mochine oa ho itšeha ka laser o potlake le o nepahetseng haholoanyane, hape o fokotsa haholo litšenyehelo tsa tlhokomelo .Ho phaella moo, ka nts'etsopele ea bohlale ba maiketsetso le thekenoloji ea boiketsetso, mechine ea laser ea ho itšeha le eona e qalile ho fallela ho tataiso e bohlale, ho finyella mekhoa e mengata e bohlale le e ikemetseng ea tlhahiso.

Ho feta moo, mechine ea ho itšeha ea laser e boetse e entse liphetoho tse ncha ho sireletsa tikoloho le ho boloka matla. Mekhoa ea setso ea ho itšeha hangata e hlahisa palo e kholo ea khase ea mouoane le masala a litšila, a bakang tšilafalo e tebileng ea tikoloho.Mochini oa ho itšeha oa laser o fokotsa ho hlahisa litšila ka ho tsepamisa mohopolo sebakeng se senyenyane bakeng sa ho itšeha, 'me ka lebaka la khase e batlang e le nyenyane ea litšila e hlahisoang nakong ea ho itšeha, e ke ke ea ama tikoloho ka ho teba. Sena se entse hore mechine ea ho itšeha ea laser e be le melemo e meholo ts'ireletso ea tikoloho le ho boloka matla, hape e fumane tlhokomelo ea 'muso le likhoebo.

Indasteri ea mochine oa ho itšeha ka laser e na le mohato oa tsoelo-pele e potlakileng. Ka tsoelo-pele e tsoelang pele ea theknoloji le kholo ea tlhokahalo ea 'maraka, mechine ea ho itšeha ka laser e tla ba le tebello e pharaletseng ea kopo. Ka nako e ts'oanang, re boetse re lebeletse mochine oa ho itšeha oa laser ho finyella ho nepahala ho phahameng le ho sebetsa hantle nakong e tlang, ho tlisa boiketlo bo eketsehileng le melemo ea moruo ho indasteri ea tlhahiso.

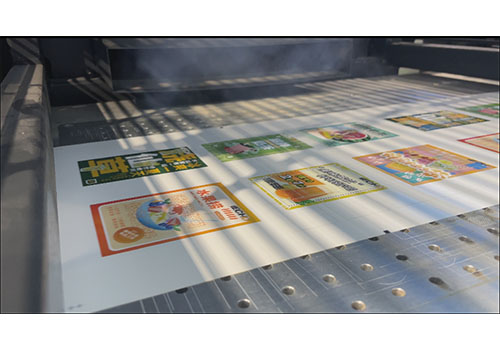

Se latelang keIECHO LCTmochini oa ho itšeha oa laser:

IECHO e ikemetse e ntlafalitse mochini oa LCT laser die-cuting ho khotsofatsa tlhoko ea 'maraka. Mochini oa ho itšeha oa laser oa LCT o kopanya theknoloji ea morao-rao le theknoloji e tsoetseng pele e tsoetseng pele, e nang le ts'ebetso e ntle haholo le ho nepahala ho itšeha, ho fana ka tharollo e nepahetseng le e sebetsang bakeng sa tlhahiso. Hase feela hore e ka finyella litlhoko tsa ho khaola ha lefu la libopeho le lisebelisoa tse sa tšoaneng, empa hape e ka finyella litlhoko tse rarahaneng tsa moralo. Ka nako e ts'oanang, ho itšeha ka lebelo le phahameng la mochini ona oa ho khaola laser oa LCT ho ka ntlafatsa haholo katleho ea tlhahiso, ho boloka nako le litšenyehelo.

Ntle le moo, ts'ebetso e ikemetseng ea mesebetsi e mengata e etsa hore ts'ebetso e be bonolo, e ntlafatsa ts'ebetso ea mosebetsi, e fihlelle tlhahiso ea boima bo ikemetseng, 'me e kenya matla a macha moleng oa tlhahiso. IECHO haesale e tsepamisitse maikutlo holim'a boqapi ba boleng le bo tsoelang pele, 'me mechine ea laser ea LCT ea ho itšeha le eona e joalo. IECHO e bile le taolo e tiileng ea boleng le tlhahlobo ho netefatsa hore mochini o mong le o mong o khona ho sebetsa ka botsitso le ka ts'epo, mme o fana ka litlamorao tse ntle haholo tsa ho itšeha. E ka sebelisoa ka kholiseho ho khotsofatsa litlhoko tse fapaneng.

Qetellong, tlhōlisano ea 'maraka bakeng sa mechine ea ho itšeha ka laser e ntse e eketseha ka bohale. Ka tlhokahalo e ntseng e eketseha ea 'maraka, bahlahisi ba eketsehileng ba mechine ea ho itšeha ka laser le bona ba ntse ba eketseha. Baetsi ba fapaneng ba ekelitse matsete ho R&D le ho ntlafatsa boleng ba sehlahisoa le ts'ebetso ho fumana karolo e kholo ea mmaraka!

Nako ea poso: Oct-23-2023