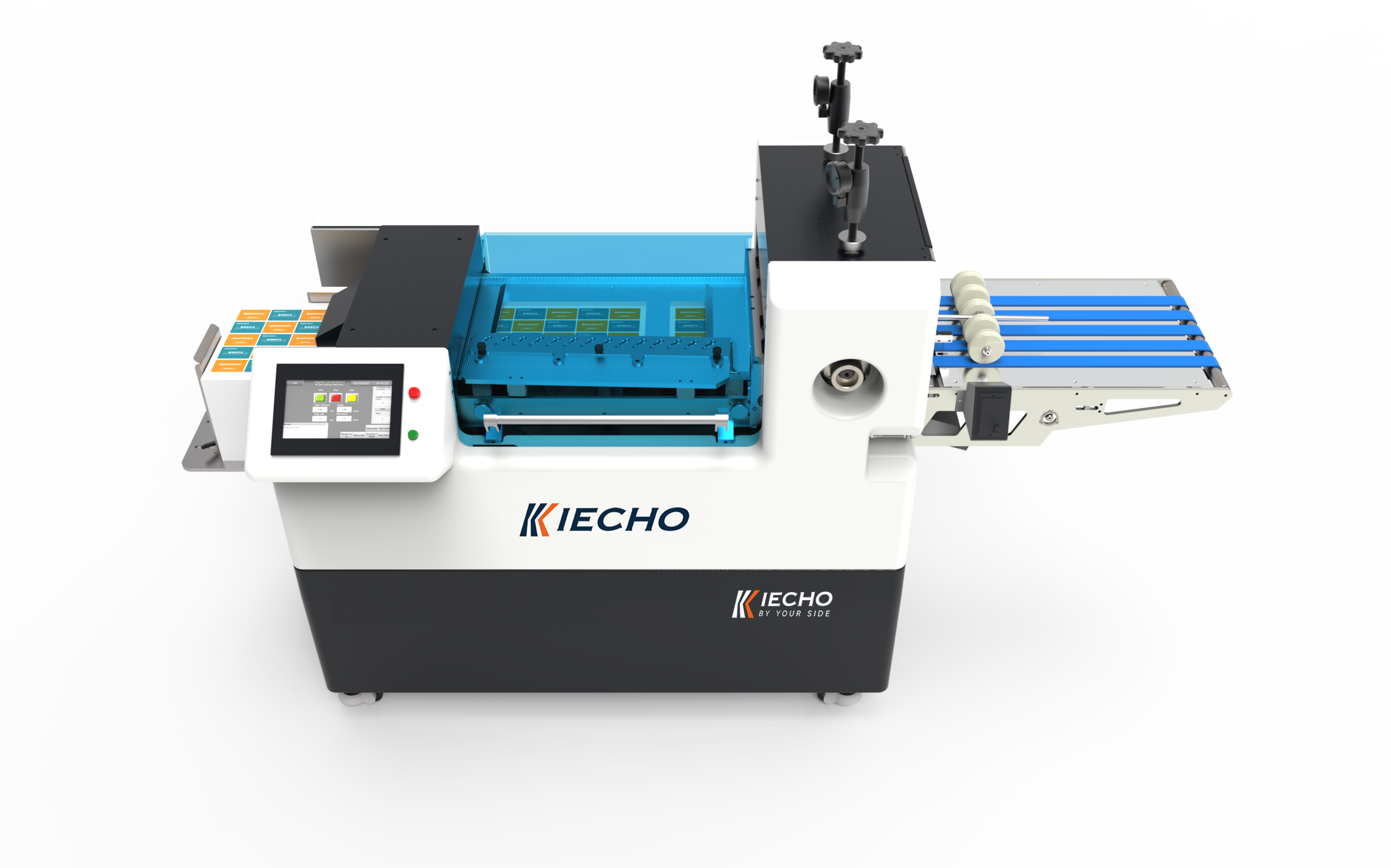

MCT Rotary die cutter

tšobotsi

kopo

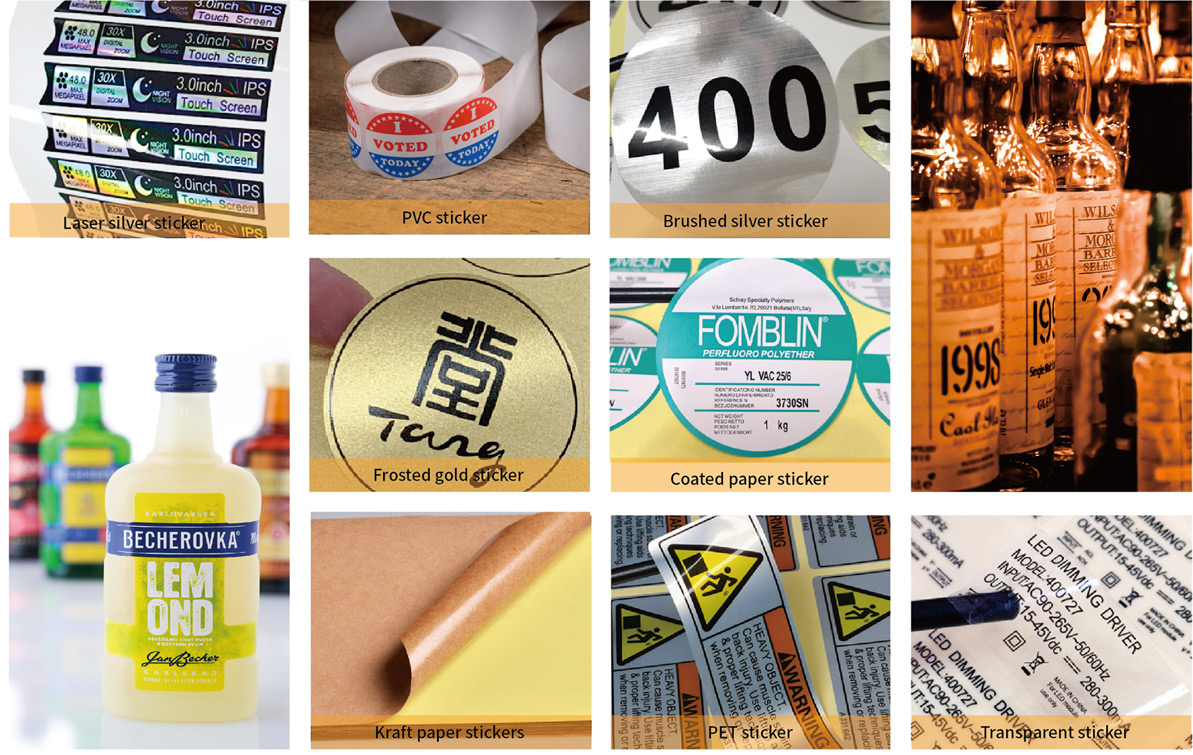

E sebelisoa haholo ho li-stickers, li-label tsa veine, li-tag tsa liaparo, likarete tsa ho bapala le lihlahisoa tse ling ho hatisa le ho paka, liaparo, lisebelisoa tsa elektroniki le liindasteri tse ling.

paramethara

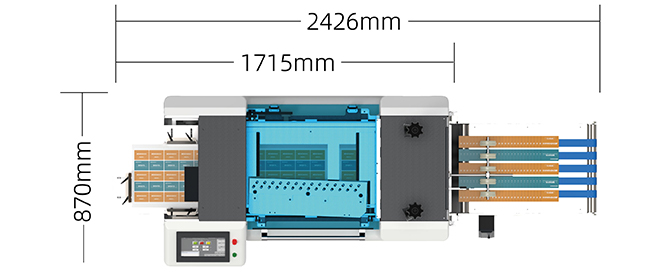

| Boholo(mm) | 2420mm × 840mm × 1650mm |

| Boima (KG) | 1000kg |

| Boholo ba boholo ba pampiri(mm) | 508mm × 355mm |

| Bonyane boholo ba pampiri(mm) | 280 limilimithara x210 limilimithara |

| Bongata ba boholo ba poleiti (mm) | 350mm × 500mm |

| Bonyane boholo ba poleiti ea die (mm) | 280 limilimithara × 210 limilimithara |

| Die plate thickness(mm) | 0.96 limilimithara |

| Ho nepahala ha ho itšeha (mm) | ≤0.2mm |

| Maximum die die cutting speed | 5000 maqephe / hora |

| Boholo ba botenya ba indentation(mm) | 0.2 limilimithara |

| Boima ba pampiri(g) | 70-400 g |

| E kenya matla a tafole (maqephe) | 1200 lipampiri |

| E kenya matla a tafole (Botenya/mm) | 250 limilimithara |

| Bophara bo fokolang ba ho lahlela litšila(mm) | 4mm |

| Matla a matla a lekantsoeng(v) | 220v |

| Reite ea matla(kw) | 6.5kw |

| Mofuta oa hlobo | Rotary shoa |

| Khatello ea sepakapaka(Mpa) | 0.6Mpa |

tsamaiso

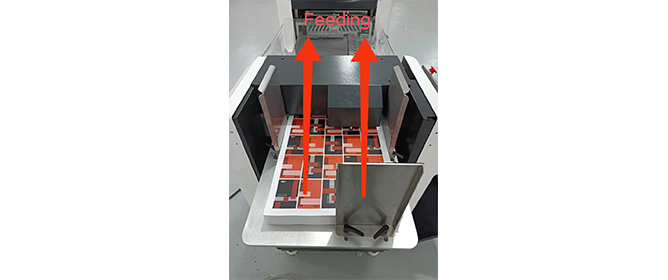

mokhoa o itekanetseng oa ho fepa

Pampiri e fepeloa ka mokhoa oa ho phahamisa terei, ebe pampiri e ebolloa ho tloha holimo ho ea tlase ka lebanta la kopi ea vacuum suction cup, ebe pampiri e monngoa ebe e isoa moleng oa conveyor oa ho kheloha o iketsang.

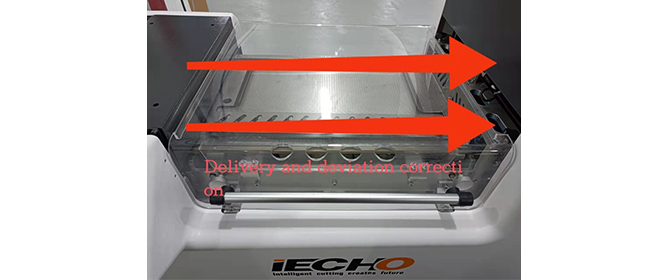

Mokhoa oa ho lokisa

Botlaaseng ba mohala oa conveyor oa ho kheloha o ikemetseng, lebanta la conveyor le kenngoa ka lehlakoreng le itseng la ho kheloha. Lebanta la conveyor angle conveyor le fetisa leqephe la pampiri le ho tsoela pele ka tsela eohle. Lehlakore le ka holimo la lebanta la ho khanna le ka fetoloa ka tsela e iketsang. Libolo li fana ka khatello ea ho eketsa khohlano pakeng tsa lebanta le pampiri, e le hore pampiri e ka khannoa pele.

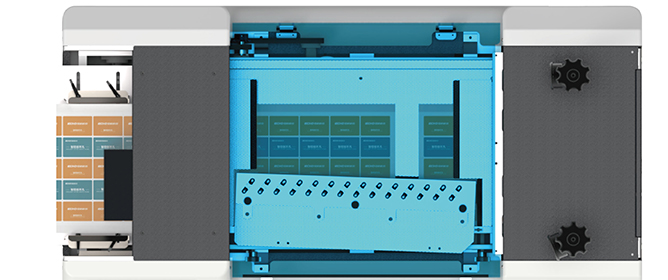

Die Cutting System

Sebopeho se lakatsehang sa paterone se sehiloe ke thipa e bilikang ea lebelo le holimo ea rolara ea makenete.

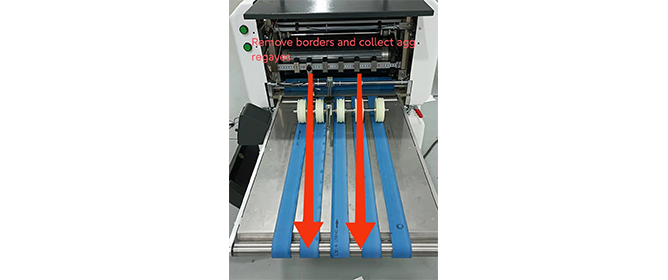

tsamaiso ea ho hana litšila

Ka mor'a hore pampiri e phuthoe le ho khaoloa, e tla feta ka har'a sesebelisoa sa ho hana pampiri ea litšila. Sesebelisoa se na le mosebetsi oa ho hana pampiri ea litšila, 'me bophara ba ho hana pampiri ea litšila bo ka fetoloa ho ea ka bophara ba mohlala.

Sistimi ea ho tsamaisa thepa

Ka mor'a hore pampiri ea litšila e tlosoe, lipampiri tse sehiloeng li thehoa ka lihlopha ka mokhoa oa morao-rao oa thepa ea lihlopha tsa conveyor line. Ka mor'a hore sehlopha se thehoe, lipampiri tse sehiloeng li tlosoa ka letsoho ho tloha moleng oa conveyor ho phethahatsa mokhoa oohle oa ho itšeha o itekanetseng.