Kwishishini lokusika iphepha lesincamathelisi, imiba efana nencakuba enxitywayo, ukusikwa ngokungachanekanga, akukho mgangatho wokusikwa, kunye nokuqokelela iLeyibhile akulunganga, njl.njl. Ukusombulula ezi ngxaki, kufuneka siphucule kwimiba emininzi efana nesixhobo, iblade, iiparamitha zokusika, imathiriyeli, kunye nokugcinwa, njl.

Okokuqala, ukukhetha i-high-precision label cutter ibalulekile. I-high-precision label cutter inokuqinisekisa ukuchaneka kokusika kunye nokunciphisa izinga lenkunkuma. Ukongezelela, ukuzinza kwe-label cutter kunempembelelo ebalulekileyo kwisiphumo sokusika. Ngethuba lenkqubo yokusika, ukunyakaza komatshini okanye ukusebenza okungazinzanga kuya kubangela ukuchaneka kokusika kuyancipha. Ngoko ke, umatshini kufuneka ugcinwe kwaye uhlolwe rhoqo ukuze kuqinisekiswe ukusebenza kwawo okuzinzile.

Okwesibini, ukukhetha izixhobo ezifanelekileyo zokusika kungundoqo ekuphuculeni umgangatho wokusika. Izixhobo zokusika ezifanelekileyo zinokuphucula isantya sokusika, ixesha lokusetyenziswa kwee-blades, kwaye ngoko ukunciphisa iindleko zokuvelisa. Xa ukhetha izixhobo zokusika, kungekhona nje kuphela ukuba ubunzima kunye nokugqoka ukuchasana kwee-blades kuthathelwe ingqalelo, kodwa kunye nokuhambelana phakathi kwezixhobo kunye ne-cutter kufuneka kuthathelwe ingqalelo.

Okulandelayo, iiparamitha zokusika ezichanekileyo nazo ziyinyathelo elibalulekileyo ekuphuculeni umgangatho wokusika. Iiparamitha zokusika ziquka isantya sokusika, uxinzelelo lokusika, ubunzulu besixhobo, njl. Izinto ezahlukeneyo zokusika kunye neentlobo zephepha lokunamathisela zineemfuno ezahlukeneyo zale parameters. Ngokuzama kunye nohlengahlengiso, ukufumana iiparamitha ezifanelekileyo zokusika kunokuqinisekisa isiphumo esihle sokusika.

Ukongeza, umgangatho wephepha lesincamathelisi unempembelelo enkulu kwisiphumo sokusika. Izinto ezikumgangatho ophezulu zinokuguquguquka okuhle, ukuchasa ukunxiba, kunye nokubambelela, eziluncedo ekuphuculeni umgangatho wokusika kunye nokunciphisa ukunxiba kwesixhobo.

Okokugqibela, ukuhlolwa rhoqo kunye nokugcinwa koomatshini kunye nezixhobo nazo ziyimfuneko. Ukufunyaniswa kwangexesha kunye nokulungisa iingxaki zokusilela kwezixhobo kunokuqinisekisa ukuqhubeka nokuzinza kwemveliso. Ngexesha elifanayo, ukutshintshwa rhoqo kwezixhobo zokunxiba kunye nokugcina izixhobo kunokunciphisa impembelelo yokugqoka isixhobo kumgangatho wokusika.

Phakathi koomatshini abaninzi bokusika, i-MCT rotary die cutter ineenzuzo ezininzi:

Ienyawo ezincinci kunye nokugcinwa kwendawo: Umatshini uhlanganisa indawo emalunga ne-2 square metres, okwenza kube lula ukuthutha kunye nokulungelelaniswa kweemeko ezahlukeneyo zemveliso.

Ukusebenza kwesikrini sokuchukumisa kwaye kulula ukuyisebenzisa.

Ukutshintsha kweencakuba ezikhuselekileyo:Itafile eyahlulahlulayo esongwayo + uyilo olujikelezayo olujikelezayo lokuchukumisa olunye ukuze kutshintshe iblade elula nekhuselekileyo.

Ukutya okuchanekileyo kunye nokukhawulezayo: Ngeqonga lokutyisa intlanzi, iphepha lilungiswa ngokuzenzekelayo ukulungelelaniswa okuchanekileyo kunye nokufikelela ngokukhawuleza kwiyunithi yokusika ukufa.

Izibonelelo ze-MCT zilele kwisantya esikhawulezayo, ukutshintsha ipleyiti ekhawulezayo, ukususwa kwe-scrap ngokuzenzekelayo, ukugcinwa kwabasebenzi kunye nomatshini kulula ukusebenza. I-blade mold ingasetyenziselwa ixesha elide .Ngoko ke, ifanelekile kakhulu kubathengi abavelisa ubuninzi, baneentlobo ezahlukeneyo zeemveliso, kwaye bafuna utshintsho oluqhelekileyo lwenguqu.

Lo matshini ufanelekile kakhulu kwimveliso yobuninzi kumashishini afana nokuprinta, ukupakishwa, ilebula yeempahla njl.

Isishwankathelo, ngokukhetha oomatshini bokusika obuchanekileyo, izixhobo zokusika ezifanelekileyo, ukulawula iiparitha zokusika, ukukhetha iphepha lesitika esiphezulu, kunye nokuhlola rhoqo kunye nokugcina izixhobo kunye nezixhobo zokusebenza, iingxaki kwinkqubo yokusika iphepha lokunamathisela zingasombululwa ngokufanelekileyo, kunye nokusika umgangatho kunye nokusebenza kakuhle kwemveliso kunokuphuculwa. Okwangoku, ukukhetha izixhobo ezifanelekileyo zokusika ezisekelwe kwiimfuno zokwenyani, njenge-MCT rotary die cutter, zinokuhlangabezana ngcono neemfuno zokusika kumashishini ahlukeneyo.

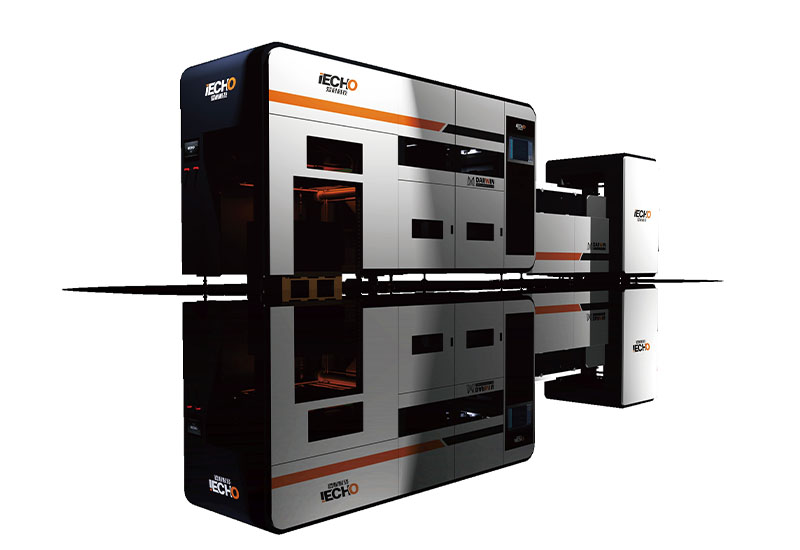

IECHO MCT rotary die cutter

Ezi matshini zilandelayo zisetyenziselwa ukusika iilebula, ezifana neLCT350 Laser Die-Cutting Machine, i-RK2-380 Digital Label Cutter kunye neDarwin Laser Die-Cutting System. Aba matshini baneempawu zabo kwaye banokuhlangabezana neemfuno zokusika iilebula kumashishini ahlukeneyo kunye neemeko.

I-IECHO LCT350 i-laser die-cutting machine yi-high-performance digital laser processing platform edibanisa ukutya okuzenzekelayo, ukulungiswa kokuphambuka ngokuzenzekelayo, ukusika i-laser flying, kunye nokususwa kwenkunkuma ngokuzenzekelayo. Iqonga lifanelekile kwiindlela ezahlukeneyo zokucwangcisa ezifana ne-roll-to-roll, roll-to-sheet, sheet-to-sheet, njl.

IECHO LCT350 laser die-cutting machine

I-RK2 ngumatshini wokusika iileyibhile odibanisa ukuqhawula, ukulahla, kunye nokuqokelela inkunkuma ngokuzenzekelayo. Ineentloko ezininzi zokusika ezilawulwa ngobulumko kwaye akukho mfuneko yokufa

IECHO RK2-380 umsiki weleyibhile yedijithali

I-Darwin laser die-cutting machine eyasungulwa yi-IECHO izise i-digital revolution kwishishini lokuprinta kunye nokupakisha, ukuguqula ixesha elide kunye neenkqubo zokuvelisa ukupakisha kwiinkqubo ezikrelekrele ngakumbi, ezikhawulezayo, kunye neziguquguqukayo ngakumbi zokuvelisa idijithali.

IECHO DARWIN inkqubo yokusika i-laser

Ixesha lokuposa: Jun-18-2024