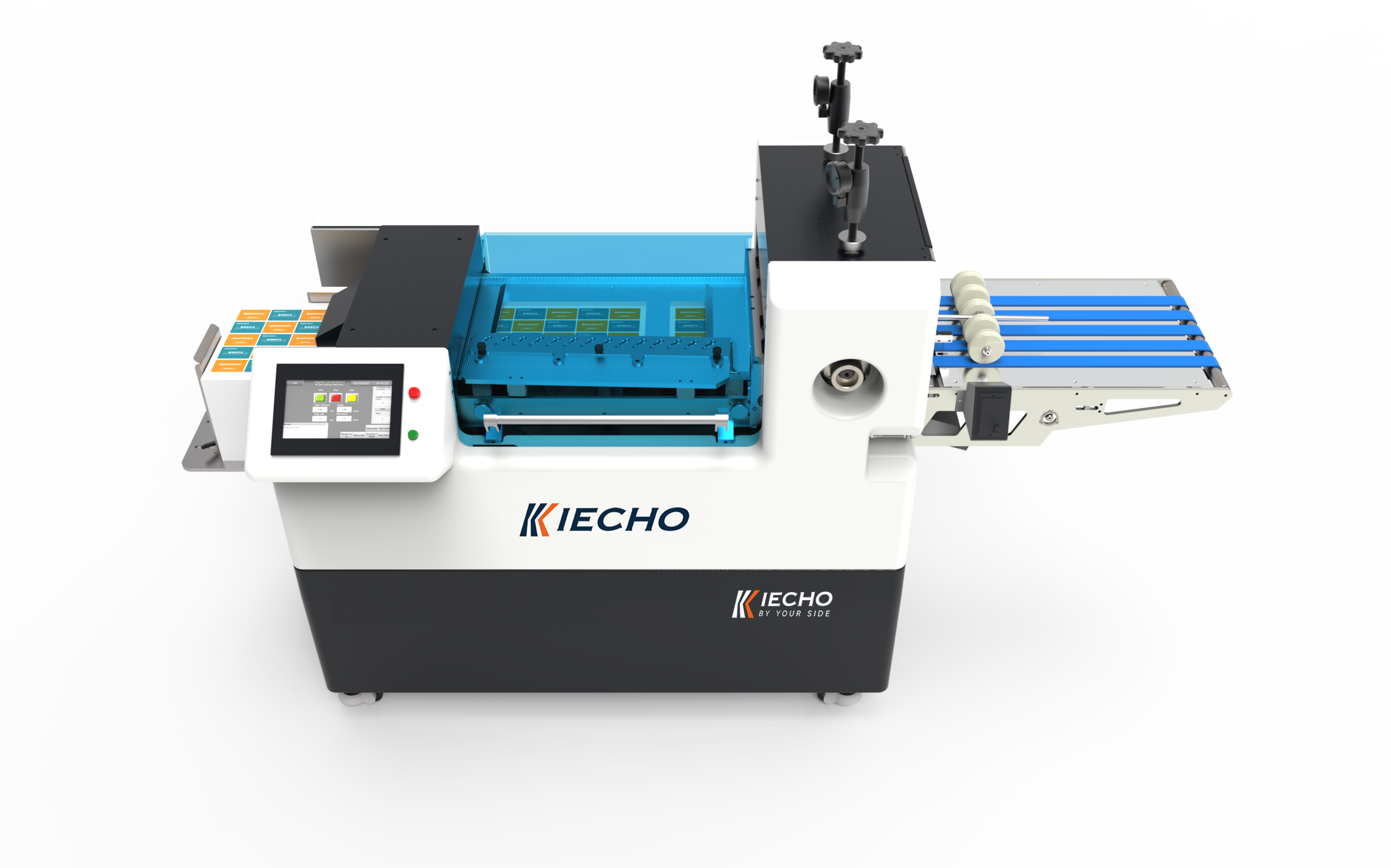

MCT Rotary die cutter

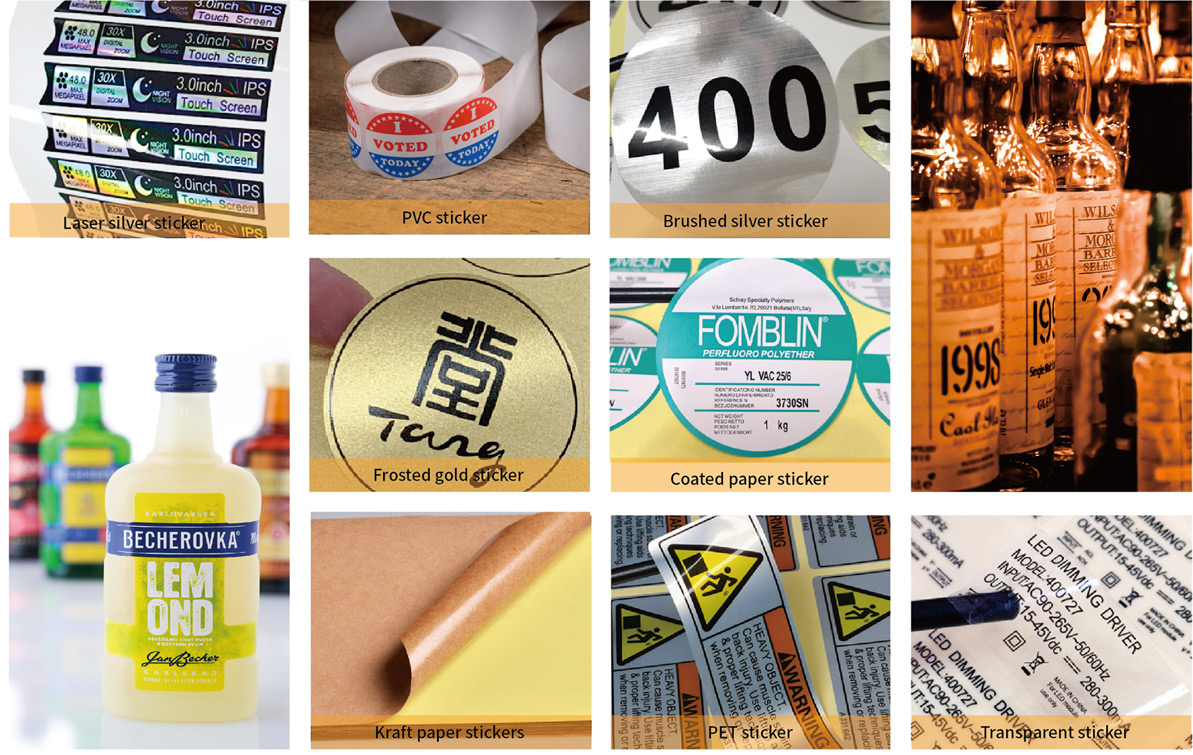

uphawu

isicelo

Isetyenziswa kakhulu kwizitikha ezincamathelayo, iilebhile zewayini, iithegi zempahla, amakhadi okudlala kunye nezinye iimveliso kushicilelo nokupakishwa, iimpahla, izinto zombane kunye namanye amashishini.

ipharamitha

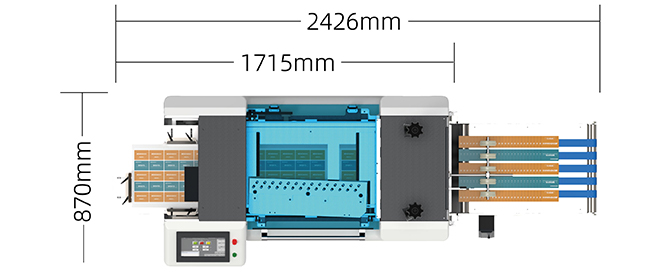

| Ubungakanani(mm) | 2420mm × 840mm × 1650mm |

| Ubunzima (KG) | 1000kg |

| Obona bukhulu bobungakanani bephepha(mm) | 508mm×355mm |

| Ubuncinci besayizi yephepha(mm) | 280mm x210mm |

| Obona bukhulu bobungakanani bepleyiti yokufa(mm) | 350mm × 500mm |

| Ubuncinci bobungakanani bepleyiti yokufa(mm) | 280mm × 210mm |

| Die plate ubukhulu(mm) | 0.96mm |

| Ukuchaneka kokufa (mm) | ≤0.2mm |

| Ubuninzi besantya sokusika ukufa | 5000 amaphepha / ngeyure |

| Obona bukhulu bobunzima bokujongwa (mm) | 0.2mm |

| Ubunzima bephepha(g) | 70-400g |

| Ilayisha umthamo wetafile (amaphepha) | 1200 amaphepha |

| Ilayisha umthamo wetafile (Ukutyeba/mm) | 250mm |

| Ubuncinci ububanzi bokulahlwa kwenkunkuma(mm) | 4mm |

| Umbane olinganisiweyo(v) | 220v |

| Ukalisho lwamandla(kw) | 6.5kw |

| Uhlobo lokungunda | Ukufa kweRotary |

| Uxinzelelo lwe-atmospheric (Mpa) | 0.6Mpa |

inkqubo

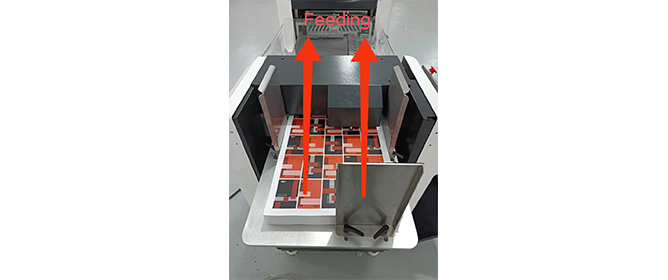

inkqubo yokutya oluzenzekelayo

Iphepha lityiswa yindlela yokunyusa itreyi, kwaye ke iphepha lixotyulwa ukusuka phezulu ukuya ezantsi ngebhanti yekomityi yokufunxa ivacuum, kwaye iphepha liyafunxwa kwaye lihanjiswe kumgca wokuhambisa ulungiso oluzenzekelayo.

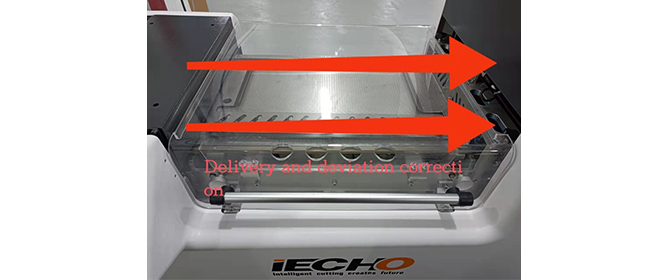

Inkqubo yokulungisa

Emazantsi kumgca wokuhambisa ukuphambuka ngokuzenzekelayo, ibhanti lokuhambisa lifakwe kwi-angle ethile yokutenxa. Ibhanti yokuhambisa i-angle yokuphambuka ihambisa iphepha lephepha kunye nenkqubela phambili yonke indlela. Icala eliphezulu lebhanti yokuqhuba liyakwazi ukulungiswa ngokuzenzekelayo. Iibhola zenza uxinzelelo lokunyusa ukudibanisa phakathi kwebhanti kunye nephepha, ukwenzela ukuba iphepha liqhutywe phambili.

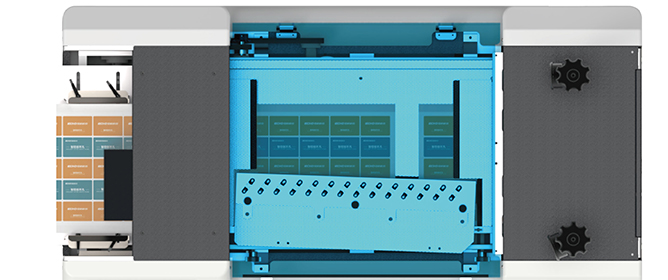

Die Cutting System

Ubume bepateni obunqwenelekayo bunqunyulwa ngesantya esiphezulu esijikelezayo semela yokusika yerola enemagnethi.

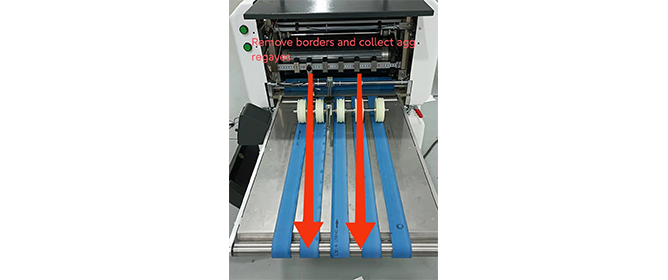

inkqubo yokulahlwa kwenkunkuma

Emva kokuba iphepha ligqitywe kwaye linqunywe, liya kudlula kwisixhobo sokulahlwa kwephepha lenkunkuma. Isixhobo sinomsebenzi wokugatya inkunkuma yephepha, kwaye ububanzi bephepha lokulahla inkunkuma bunokulungelelaniswa ngokobubanzi bepateni.

Inkqubo yokuhanjiswa kwezinto

Emva kokuba iphepha lenkunkuma lisusiwe, amaphepha asikiweyo ayenziwa abe ngamaqela ngokusebenzisa umgca we-rear-stage material grouping grouping line. Emva kokuba iqela lenziwe, amaphepha anqunyulwe asuswa ngesandla kumgca wokuhambisa ukugqiba yonke inkqubo yokusika ngokuzenzekelayo.