Embonini yokusika amaphepha ezitikha, izinkinga ezifana ne-blade egqokwayo, ukusikwa ngokunganembiki, akukho okushelelayo kokusikwa, kanye nokuqoqwa Kwelebula akukuhle, njll. Ukuze sixazulule lezi zinkinga, sidinga ukuthuthukisa kusukela ezicini eziningi ezifana nedivayisi, i-blade, imingcele yokusika, izinto zokwakha, nokugcinwa, njll.

Okokuqala, ukukhetha umsiki welebula wokunemba okuphezulu kubalulekile. I-High-precision label cutter ingaqinisekisa ukunemba kokusika futhi yehlise izinga lokumosha. Ngaphezu kwalokho, ukuzinza komsiki welebula kunomthelela obalulekile emphumeleni wokusika. Phakathi nenqubo yokusika, ukudlidliza komshini noma ukusebenza okungazinzile kuzobangela ukunemba kokusika kwehle. Ngakho-ke, umshini udinga ukunakekelwa futhi uhlolwe njalo ukuze kuqinisekiswe ukusebenza kwawo okuzinzile.

Okwesibili, ukukhetha amathuluzi okusika afanelekile kuyisihluthulelo sokuthuthukisa ikhwalithi yokusika. Amathuluzi okusika afanelekile angathuthukisa isivinini sokusika, isikhathi sokusebenzisa ama-blades, futhi ngaleyo ndlela anciphise izindleko zokukhiqiza. Uma ukhetha amathuluzi okusika, akufanele nje kucatshangelwe ubunzima kanye nokumelana nokugqoka kwama-blades, kodwa futhi ukuhambisana phakathi kwamathuluzi kanye nomsiki kufanele kucatshangelwe.

Okulandelayo, isethi enengqondo yokusika imingcele nayo iyisinyathelo esibalulekile sokuthuthukisa ikhwalithi yokusika. Imingcele yokusika ihlanganisa isivinini sokusika, ingcindezi yokusika, ukujula kwamathuluzi, njll. Izinto zokusika ezihlukene kanye nezinhlobo zephepha lesitika zinezidingo ezihlukene zale mingcele. Ngokuhlola nokulungiswa, ukuthola imingcele yokusika efaneleke kakhulu kungaqinisekisa umphumela omuhle kakhulu wokusika.

Ngaphezu kwalokho, ikhwalithi yephepha lesitika nayo inomthelela omkhulu emthelela wokusika. Izinto zekhwalithi ephezulu zinokuguquguquka okuhle, ukumelana nokugqoka, nokunamathela, okuyinzuzo ekuthuthukiseni ikhwalithi yokusika nokunciphisa ukugqokwa kwamathuluzi.

Okokugcina, ukuhlolwa nokunakekelwa njalo kwemishini namathuluzi nakho kubalulekile. Ukutholwa ngesikhathi kanye nokuxazululwa kwezinkinga zokwehluleka kwemishini kungaqinisekisa ukuqhubeka nokuzinza kokukhiqiza. Ngesikhathi esifanayo, ukushintsha njalo amathuluzi okugqoka nokugcina okokusebenza kunganciphisa umthelela wokugqoka kwamathuluzi kwikhwalithi yokusika.

Phakathi kwemishini eminingi yokusika, i-MCT rotary die cutter inezinzuzo eziningi:

Izinyawo ezincane nokonga isikhala: Umshini uhlanganisa indawo ecishe ibe ngamamitha-skwele angu-2, okwenza kube lula ukuthutha futhi ifanele izimo zokukhiqiza ezihlukene.

Ukusebenza kwesikrini sokuthinta futhi kulula ukuyisebenzisa.

Ukushintsha ama-blade aphephile:Ithebula eligoqayo eligoqayo + idizayini yerola ezungezayo yokuthinta okukodwa ukuze kube nezinguquko ezilula neziphephile zeblade.

Ukondla okunembile nokusheshayo: Ngenkundla yokudla esikalini sezinhlanzi, iphepha lilungiswa ngokuzenzakalelayo ukuze liqondaniswe kahle futhi lifinyelele ngokushesha kuyunithi yokusika ukufa.

Izinzuzo ze-MCT zisejubaneni layo elisheshayo, ukuguqulwa kwamapuleti asheshayo, ukususwa kwe-scrap okuzenzakalelayo, ukonga abasebenzi kanye nomshini kulula ukuwusebenzisa. Isikhunta se-blade singasetshenziswa isikhathi eside .Ngakho-ke, kufanelekile kakhulu kumakhasimende akhiqiza ngobuningi, anemikhiqizo ehlukahlukene, futhi adinga izinguquko zenguqulo evamile.

Lo mshini ufanelekile kakhulu ekukhiqizeni ngobuningi ezimbonini ezifana nokunyathelisa, ukupakisha, ilebula yezingubo njll. Ungaphinda ufakwe isiteji sokuqoqa izinto ezizenzakalelayo ngokugcwele ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza.

Kafushane, ngokukhetha imishini yokusika enembayo ephezulu, amathuluzi okusika afanelekile, ukulawula imingcele yokusika, ukukhetha iphepha lokunamathisela lekhwalithi ephezulu, nokuhlola njalo nokugcina imishini namathuluzi, izinkinga ohlelweni lokusika iphepha lokunamathisela zingaxazululwa ngempumelelo, futhi izinga lokusika kanye nokusebenza kahle kokukhiqiza kungathuthukiswa. Khonamanjalo, ukukhetha imishini yokusika efanelekile esekelwe ezidingweni zangempela, njenge-MCT rotary die cutter, ingahlangabezana kangcono nezidingo zokusika zezimboni ezihlukahlukene.

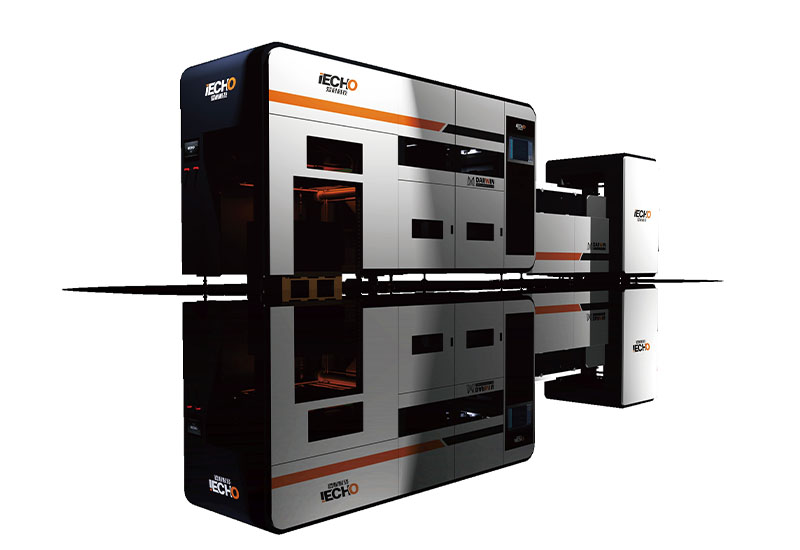

I-IECHO MCT rotary die cutter

Imishini elandelayo iphinde isetshenziswe ekusikeni ilebula, njenge-LCT350 Laser Die-Cutting Machine, i-RK2-380 Digital Label Cutter kanye ne-Darwin Laser Die-Cutting System. Le mishini inezici zayo futhi ingahlangabezana nezidingo zokusika ilebula ezimbonini nasezimeni ezahlukene.

Umshini wokusika i-laser we-IECHO LCT350 iyinkundla yokucubungula i-laser yedijithali esebenza kahle kakhulu ehlanganisa ukuphakela okuzenzakalelayo, ukulungiswa kokuphambuka okuzenzakalelayo, ukusika okundiza nge-laser, kanye nokukhipha imfucuza okuzenzakalelayo. Iplatifomu ifanele izindlela ezihlukene zokucubungula ezifana ne-roll-to-roll, roll-to-sheet, sheet-to-sheet, njll.

I-IECHO LCT350 laser die-cutting machine

I-RK2 iwumshini wokusika ilebula ohlanganisa ukusika, ukugawula, nokuqoqwa kukadoti okuzenzakalelayo. Inamakhanda okusika amaningi alawulwa ngobuhlakani futhi asikho isidingo sokufa

IECHO RK2-380 umsiki welebula yedijithali

Umshini wokusika umshini we-laser we-Darwin owethulwe yi-IECHO ulethe uguquko lwedijithali embonini yokunyathelisa nokupakisha, ukuguqula izinqubo zokukhiqiza ukupakisha ezidla isikhathi nezikhandlayo zibe izinqubo zokukhiqiza ezihlakaniphe kakhulu, ezisheshayo nezivumelana nezimo kakhudlwana.

I-IECHO DARWIN laser die-cutting system

Isikhathi sokuthumela: Jun-18-2024