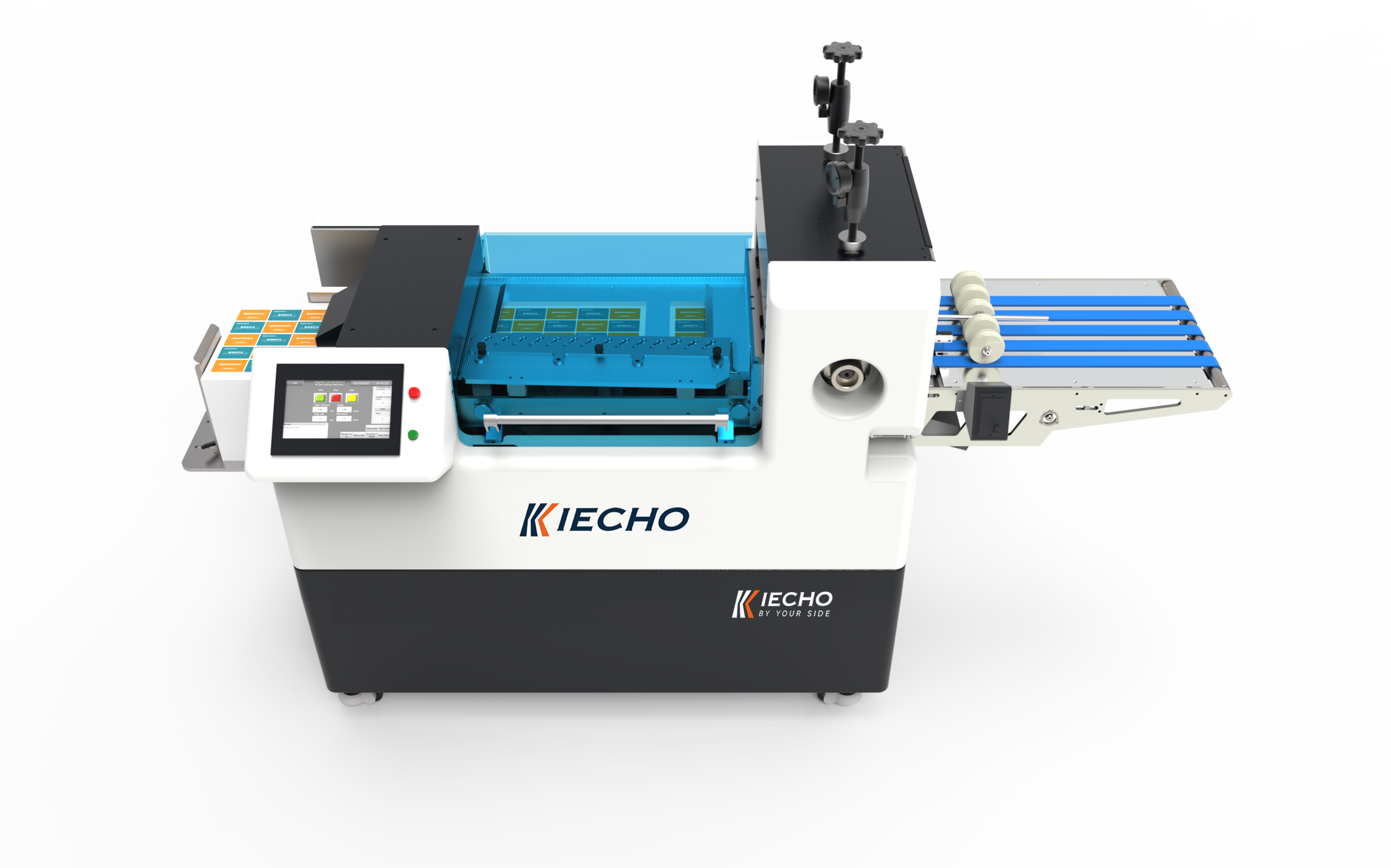

I-MCT Rotary die cutter

isici

isicelo

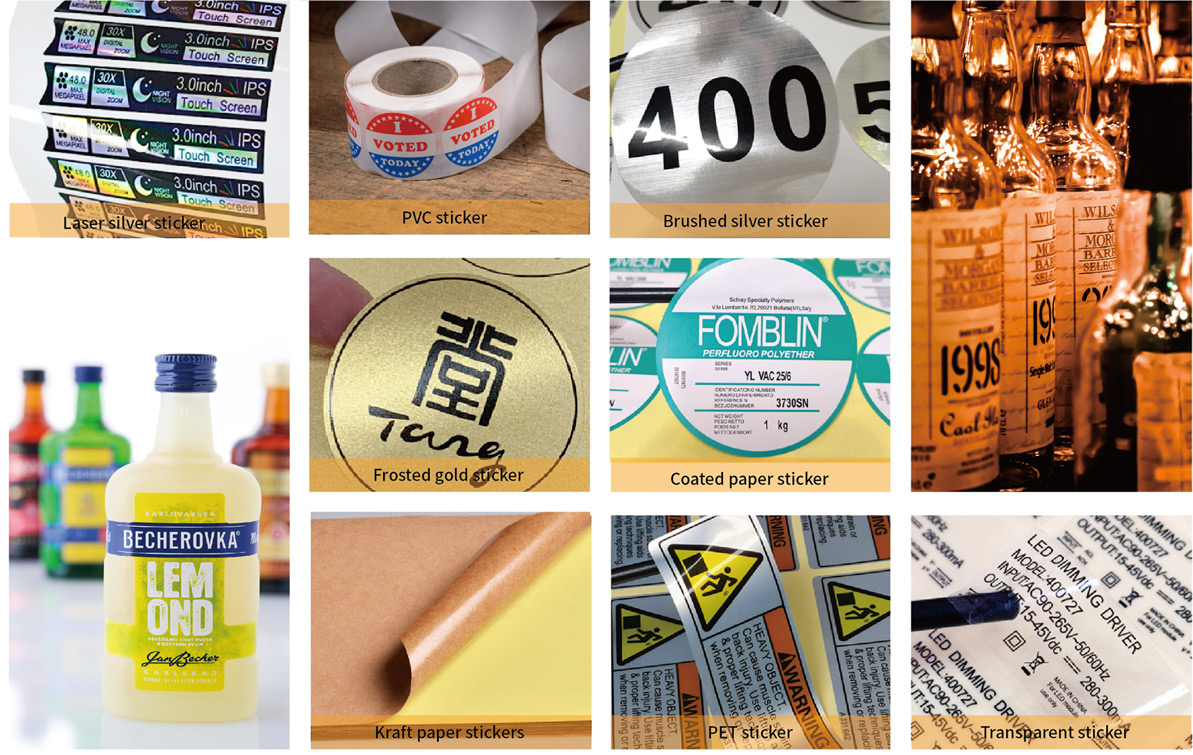

Isetshenziswa kakhulu kuzitika zokuzinamathisela, amalebula ewayini, omaka bezingubo, amakhadi okudlala neminye imikhiqizo ekuphrinteni nasekupakisheni, izingubo zokugqoka, izinto zikagesi nezinye izimboni.

ipharamitha

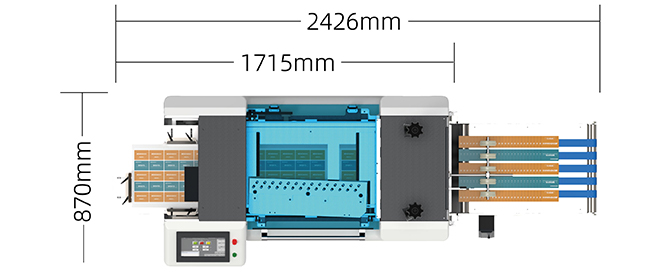

| Usayizi(mm) | 2420mm × 840mm × 1650mm |

| Isisindo (KG) | 1000kg |

| Umkhawulo kasayizi wephepha(mm) | 508mm×355mm |

| Ubuncane bosayizi wephepha(mm) | 280mm x210mm |

| Ubukhulu bosayizi wepuleti lokufa(mm) | 350mm × 500mm |

| Ubuncane bepuleti lokufa(mm) | 280mm × 210mm |

| Ubukhulu bepuleti lokufa(mm) | 0.96mm |

| Ukunemba kokufa (mm) | ≤0.2mm |

| Isivinini esikhulu sokusika | 5000 amashidi/ihora |

| Ubuningi bokuhlehlisa obukhulu(mm) | 0.2mm |

| Isisindo sephepha(g) | 70-400 g |

| Ilayisha umthamo wetafula (amashidi) | 1200 amashidi |

| Ilayisha umthamo wetafula (Ubukhulu/mm) | 250mm |

| Ububanzi obuncane bokuchithwa kwemfucuza(mm) | 4mm |

| I-voltage elinganiselwe(v) | 220v |

| Isilinganiso samandla(kw) | 6.5kw |

| Uhlobo Lwesikhunta | Ukufa kwe-Rotary |

| Umfutho we-atmospheric (Mpa) | 0.6Mpa |

uhlelo

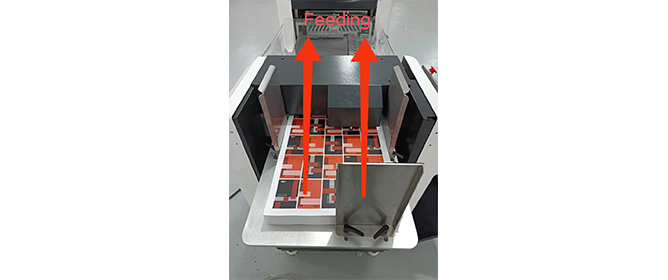

uhlelo lokudla okuzenzakalelayo

Iphepha liphakelwa indlela yokuphakamisa ithreyi, bese iphepha liyahlutshwa ukusuka phezulu kuye phansi ngebhande lenkomishi yokumunca i-vacuum, futhi iphepha liyamuncwa futhi lihanjiswe kulayini wokuqondisa ukuchezuka okuzenzakalelayo.

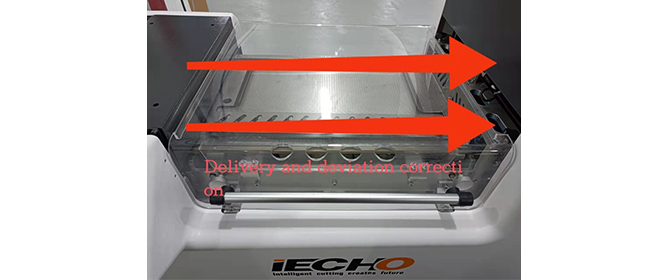

Isistimu yokulungisa

Phansi kolayini wokulungisa ukuchezuka othomathikhi, ibhande le-conveyor lifakwa nge-engeli ethile yokuchezuka. Ibhande le-deviation angle conveyor lidlulisa ishidi lephepha futhi liqhubekele phambili yonke indlela. Uhlangothi olungenhla lwebhande lokushayela lungalungiswa ngokuzenzakalelayo. Amabhola enza ingcindezi yokwandisa ukungqubuzana phakathi kwebhande nephepha, ukuze iphepha liqhutshwe phambili.

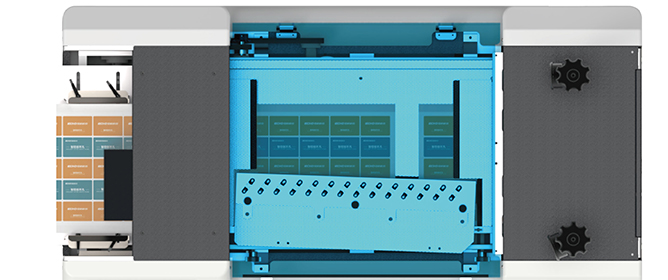

I-Die Cutting System

Umumo wephethini owufiswayo usikwa ngokufa ngommese oguquguqukayo onesivinini esikhulu oguquguqukayo werola kazibuthe.

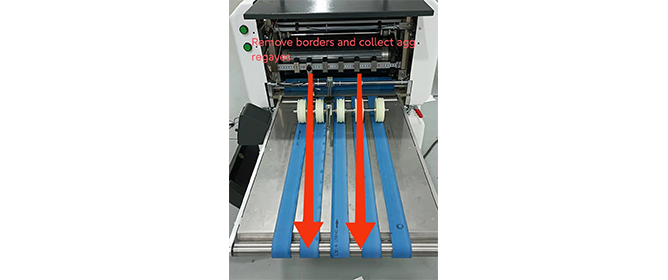

uhlelo lokulahla imfucuza

Ngemuva kokuthi iphepha ligoqwe futhi lisikiwe, lizodlula kudivayisi yokulahla iphepha elibi. Idivayisi inomsebenzi wokwenqaba imfucuza yephepha, futhi ububanzi bokwenqaba imfucuza yephepha bungalungiswa ngokuvumelana nobubanzi bephethini.

Isistimu yokudlulisa impahla

Ngemva kokususwa kwephepha lemfucuza, amashidi asikiwe akhiwa abe ngamaqembu ngokusebenzisa umugqa wokuthutha weqoqo lezinto ezingemuva. Ngemuva kokuthi iqembu selisungulwe, amashidi asikiwe asuswa ngesandla emgqeni wokuthutha ukuze aqedele lonke uhlelo lokusika oluzenzakalelayo.